- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

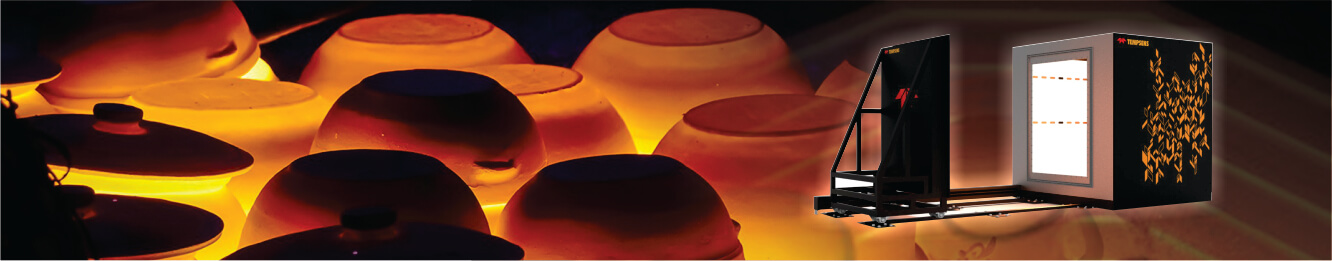

High Temperature Front Loading Furnace

High temperature front loading furnaces are another type of Industrial furnace that is capable of reaching higher temperatures ≈1750°C, specially used in various industrial processes such as heat treating, annealing, sintering, and mic production. These high temperature front loading furnaces are specially designed for heavy and large material loading. The loading, unloading and opening and closing of doors can be controlled manually or through PLC. According to the processes forced air and vent flap, equipment size, gas mixing and delivery system are recommended.

We use specially designed heating elements which help us to get precise and extreme temperatures up to 1750°C to alter the physical or chemical properties of materials. These furnaces are equipped with advanced insulation materials to minimize heat loss to increase its efficiency to meet specific manufacturing or research needs.

Why to choose High Temperature Front loading Furnaces

- Temperature Uniformity: Achieving and maintaining uniform temperature distribution within the furnace chamber is critical for consistent and high-quality results. Advanced control systems and heating elements in high-temperature front loading furnaces ensure precise temperature uniformity, guaranteeing that every part of the load undergoes the desired heat treatment.

- Front Loading Design: The front loading configuration is a hallmark of these furnaces, allowing easy access to the chamber for loading and unloading. This design is not only convenient for operators but also enhances safety and efficiency in the workplace. With front loading, it becomes possible to seamlessly integrate these furnaces into existing production lines.

- Advanced Insulation Materials: To withstand extreme temperatures, these furnaces are equipped with state-of-the-art insulation materials. High-quality refractories and insulating bricks form a protective barrier, minimizing heat loss and ensuring the exterior of the furnace remains cool to the touch despite the blistering temperatures within.

- Precise Temperature Control: Temperature control is the heart of any high-temperature furnace. These advanced furnaces are equipped with sophisticated control systems that enable precise adjustments to meet the specific thermal processing requirements of different materials. This level of control is crucial for achieving desired material properties and minimizing the risk of thermal shock.

Applications of High Temperature Front loading Furnaces:

- Metallurgy: High-temperature front loading furnaces find extensive use in the metallurgical industry for processes like annealing,

hardening, and tempering of metals. The ability to reach and maintaing ultra-high temperatures makes them ideal for treating exotic alloys and specialized materials.

hardening, and tempering of metals. The ability to reach and maintaing ultra-high temperatures makes them ideal for treating exotic alloys and specialized materials. - Research and Development: In research and development laboratories, where the exploration of new materials and processes is constant, high-temperature front loading furnaces serve as invaluable tools. Researchers can simulate extreme conditions and study material behavior at temperatures not achievable with conventional furnaces.

- Ceramics and Composites: The field of advanced ceramics and composite materials benefits greatly from the capabilities of these furnaces. Processes like sintering and hot

pressing, essential for creating high-performance ceramics and composites, require the precision and high temperatures that these furnaces provide.

pressing, essential for creating high-performance ceramics and composites, require the precision and high temperatures that these furnaces provide.

As a furnace specializing in high-temperature front loading equipment, it's clear these furnaces represent the pinnacle of thermal processing technology. Their ability to operate at temperatures up to 1750 degrees Celsius, combined with features such as front loading design and precise temperature control, make them indispensable in industries where thermal processing is a critical component. As technology continues to advance, these furnaces will undoubtedly play a crucial role in shaping the future of materials science and industrial manufacturing.

Features of High temperature front loading furnace

- Maximum Temperature up to 1750°C.

- Customizable volume.

- Fast Heating and cooling.

- High Uniformity up to +/-5°C.

- Multi segment Microprocessor Based Programmable Temperature Controller.

- High quality MoSi2 elements for continuous working up to 1750°C

- The loading, unloading and opening and closing of doors can be controlled manually or through PLC.

Why to Choose Tempsens

Tempsens is a distinguished leader with a legacy spanning over 45 years. Tempsens has carved its niche by combining innovative technology with a commitment to quality in the realm of thermal solutions and cables.

- Provides a compact design thus saving floor space.

- Able to deliver more uniform process heat.

- Easy loading and unloading procedure.

- Highly reliable automatic process control systems.

- Ease of operation and maintenance.

- Convenient for heavy, large, or high-volume workloads.

In the realm of heat treatment, precise temperature control and quality assurance are paramount. Choosing Tempsens as the trusted partner ensures not just cutting-edge technology but also the assurance of over four decades of invaluable experience. We at Tempsens manufacture both Industrial and Laboratory Furnace and Ovens for varied applications which include sintering,annealing, tempering and calcination. The furnaces and ovens manufactured come in varied sizes and volume as per the application requirement.

For details visit at: https://tempsens.com/catalog/industrial-furnaces.html