- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

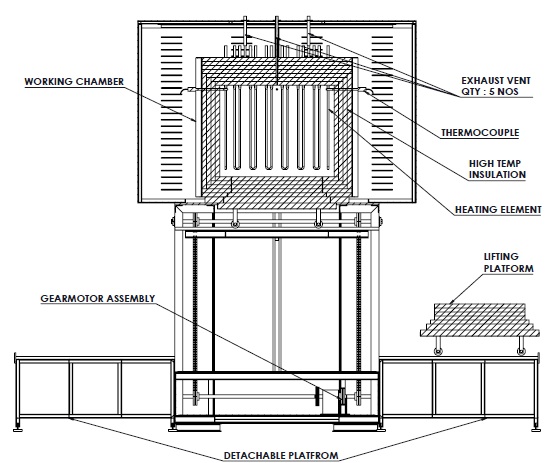

Bottom Loading Furnace

What is BLF(Bottom Loading Furnace)?

As the name suggests, material loading in the BLF is done from the bottom side. It means that the door is fitted at the bottom, which is lifted or lowered with a smooth motor drive mechanism. Loading of material is done on the door itself (loading platform).

Why BLF(Bottom Loading Furnace) is used?

Heating elements are fitted on all four sides of the inner chamber thus providing the most uniform heat distribution. Loading and unloading of material is easy with help of a lifting platform. Bottom-loading furnaces are ideal for achieving a wide range of heating-cooling cycles while maintaining temperature uniformity and product quality. BLF is convenient for heavy, large, or high-volume workloads.

Working of BLF -Bottom Loading Furnace

BLF Bottom Loading Furnaces uses electrically operated motor gear assembly to raise and lower the loading platform with precision. Loading and unloading time is kept minimum while avoiding any impact.

Application of BLF -Bottom Loading Furnace

| Melting | Sintering | Ceramic injection molding(CIM) | Calcining |

| Soldering | Degassing | Metal injection molding(MIM) | Brazing |

| Drying | Debinding | Rapid prototyping | Hardening |

| Tempering | Synthesis | siliconization | Quenching |

| sublimation | Firing | Carbonization | pyrolysis |

| Annealing | Thermistors | Ferroelectric application | capacitors |

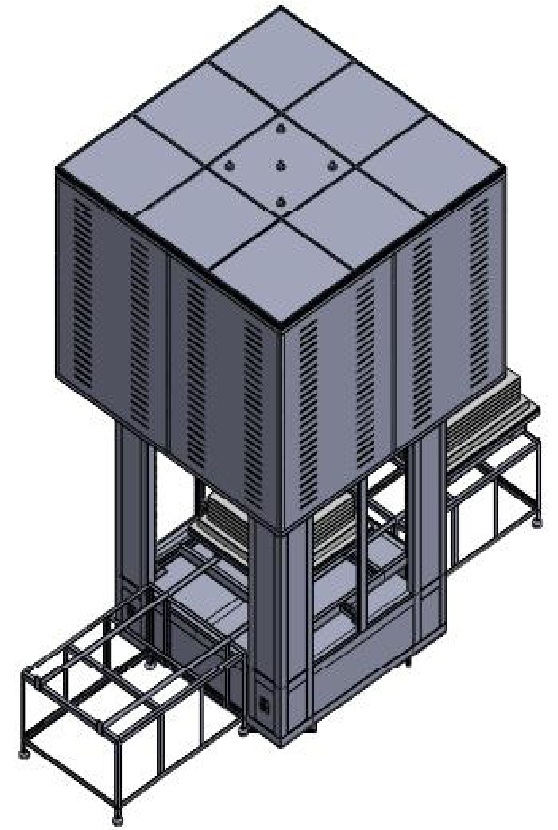

BLF-Bottom Loading Furnace by Tempsens

Tempsens is a leading manufacturer of high-quality Indigenous furnaces. We provide bottom loading furnaces up to the maximum temperature of 1800 C. we offer bottom loading furnaces in standard models. These bottom loading furnaces can be custom designed and built to suit the needs of the customer.

These Tempsens make Bottom loading furnaces are having a robust structure with greater durability, are versatile in application, and are designed for easier operation and maintenance. We at Tempsens believe in using the best quality material and equipment for the manufacturing of furnaces. These furnaces are reliable in operation and have a long life.

We manufacture a great variety of BLF ranging from 1.8 liters to 1331 liters of volume depending upon customer requirements.

Standard models

| Model | Volume(liters) | Power | Controlling T/C | Heating Element |

| BLF – 1200 | 1.8 | 2.8 | N | FeCrAl |

| BLF – 1800 | 1.8 | 3.0 | R | Silicon Carbide |

| BLF – 1500 | 1.8 | 3.0 | B | MoSi2 |

Standard features

- Bottom loading arrangement

- Safety controller for overheat protection

- Door safety limit switch

- Thermocouple break protection

Optional features

- Provision for gas/vacuum purging

- Programmable PID controller with RS-232/RS-485/Ethernet

- Data logger software

Advantages

- Easy loading and unloading of material

- Smooth motor-driven door lifting mechanism

- Uniform temperature distribution

- Fast cooling

- Low heat loss

- Easy maintenance

For more details visit at Bottom Loading Furnaces - BLF