- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

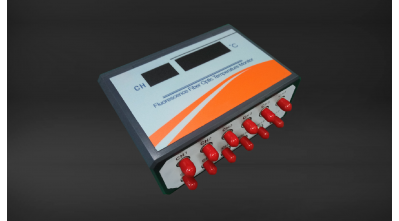

FluoroSenz Fiber Optic Temperature Monitoring System conducts real time monitoring to accurately measure point temperatures of hotspots including Transformers, Switchgears, Generators. It is specially designed for harsh environment where High Electric and Magnetic fields are present. The system is based on Calibration free Fluorescence Time Decay Technology, which ensures no recalibration is required over the lifespan of the sensor. The size of Optical Fiber Sensor is very small and it can be easily installed on the measuring point with high measurement accuracy and fast response frequency. Supporting up to 16 Sensors, the temperature of each can be read on the local 7-Segment Display or remotely monitored on PC through various communication provided. The system is supplied with a User Friendly Software which shows real-time data readings along with graphical representation.

The System is based on Fluorescence Time Decay of a Rare-Earth Fluorescence Sensor formed on the tip of the Optical Fiber. The other end of the fiber is attached to a light source which is used to excite the Fluorescent material. After excitation, the excited fluorescent material tends to return from its peak state to ground state by emitting a photon (light). This time taken to reach to the ground state is dependent on the ambient temperature and thus temperature is deduced by forming a relation between Time Decay and Temperature.

Fluorescence Based Fiber Optic Temperature Sensors Models

Fiber Optic Temperature Sensor for Switchgear Busbar

The TQ-12 type fiber optic temperature monitoring systems from Tempsens offers real time and condition based temperature monitoring of Switchgear hot spot which gives situational awareness of Switchgear health and keep equipment from catastrophe failure.

FluoroSenz Fiber Optic Temperature Monitoring System

Fiber optic temperature monitoring system that is designed for point measurement in a range of applications like as energy, oil & gas, and various industries. It is best suited for precise and accurate measurements in harsh conditions.