- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Mineral insulated heating cables provide rugged, high temperature and reliable heat tracing for different customize applications. MI cables constructed by high nickel alloy sheath materials, magnesium oxide dielectric insulation, and resistance wire construction allow the tracing of surface up to 600°C maintain temperatures and excellent resistance to harsh & many corrosive environments. MI heating cables and heater units are widely used in areas where high temperature, high pressure, high radiation, or corrosive environments exist, and where high power density field, and electric heating or heating processes exist.

Advantages

- High power output due to the perfect thermal conductivity of the metallic sheath.

- Reduced size due to the high dielectric strength of the magnesium oxide while maintaining good thermal conductivity.

- Easy installation due to its reduced size and annealed state of the outer sheath.

- High flexibility during the design phase, due to the wide range of available resistances.

- Factory assembled cable sets ready for installation

- The fully annealed sheath allows field bending

- Corrosion-resistant sheath

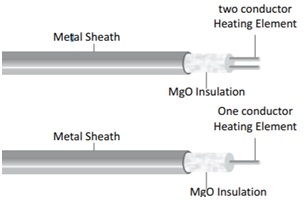

Construction

Metal Sheath: High nickel content Alloy 600 & 825 is recognized for its use in high-temperature applications, and use in many corrosive environments. This alloy has excellent resistance to pitting, acid, and alkali corrosion. Stainless steel alloys are also available.

MgO: Highly compacted Magnesium Oxide provides insulation of the resistance Wire. A completely sealed sheath protects the MgO from moisture & contamination.

Resistance Wire: A large number of available resistances enables the design of a large range of lengths and wattage. Double and single conductors available.

- Voltage

Up to 600V

- Cold Resistance Tolerance

≤3%

- Heating Element

Ferritic Alloys- Powder metallurgical element, Mara FeCrAl, NiCr 80/20

- Temperature Range

Up to 600°C

- Sheath Materials

Nickel Alloys 600/ 825, Stainless steel Alloys SS304, SS316, SS321

- Heating Parameters

Customized - Power rating, voltage, resistance, length, diameter, and other dimensions

Special Heating Cable Design Configurations

Marathon Heater offers customized designs in MI Heater Configurations to fulfill customer requirements. Marathon Heater ECR (Extended Cold Region) Heaters are examples of such special type of MI Heaters, which are manufactured with extended cold ends from the Heating Length of the heater which suits Critical Nuclear applications.

- Wattage and voltage customized to the application

- Elements can be formed to specification or formed on location

- The optional internal thermocouple can be located at various points for precise temperature control

- Sealed lead wire transition eliminates contamination

- Sheath materials were available in 304 stainless steel, 316 stainless steel, Inconel® 600, or custom material available upon request.

Application Areas

- Heat Trace / Freeze Protection

- Semiconductor Manufacturing

- Plastic Molding Hot Runners Systems

- Air or Liquid Immersion

- Cutting and Sealing Bars

- Tube and Pipe Heating

- Large Surface Areas

- Vacuum Chambers