- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

We have a world-class manufacturing plant for producing a wide range of Mineral insulated (MI Cable), metal-sheathed cable. The applications of MI Cable are many such as blast furnaces, atomic research, nuclear reactors, Kilns, and many more. We provide standard as well as custom-built cables as per the customer's need/ application requirement. We have very flexible lines so always ready to meet the demand.

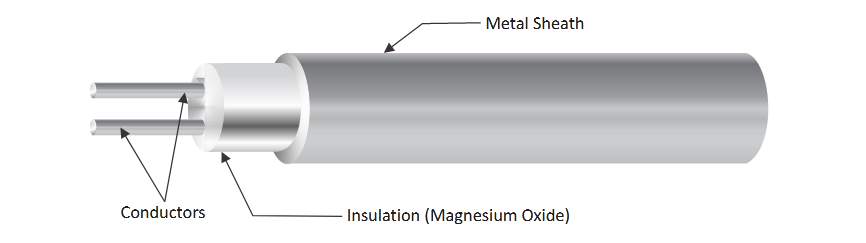

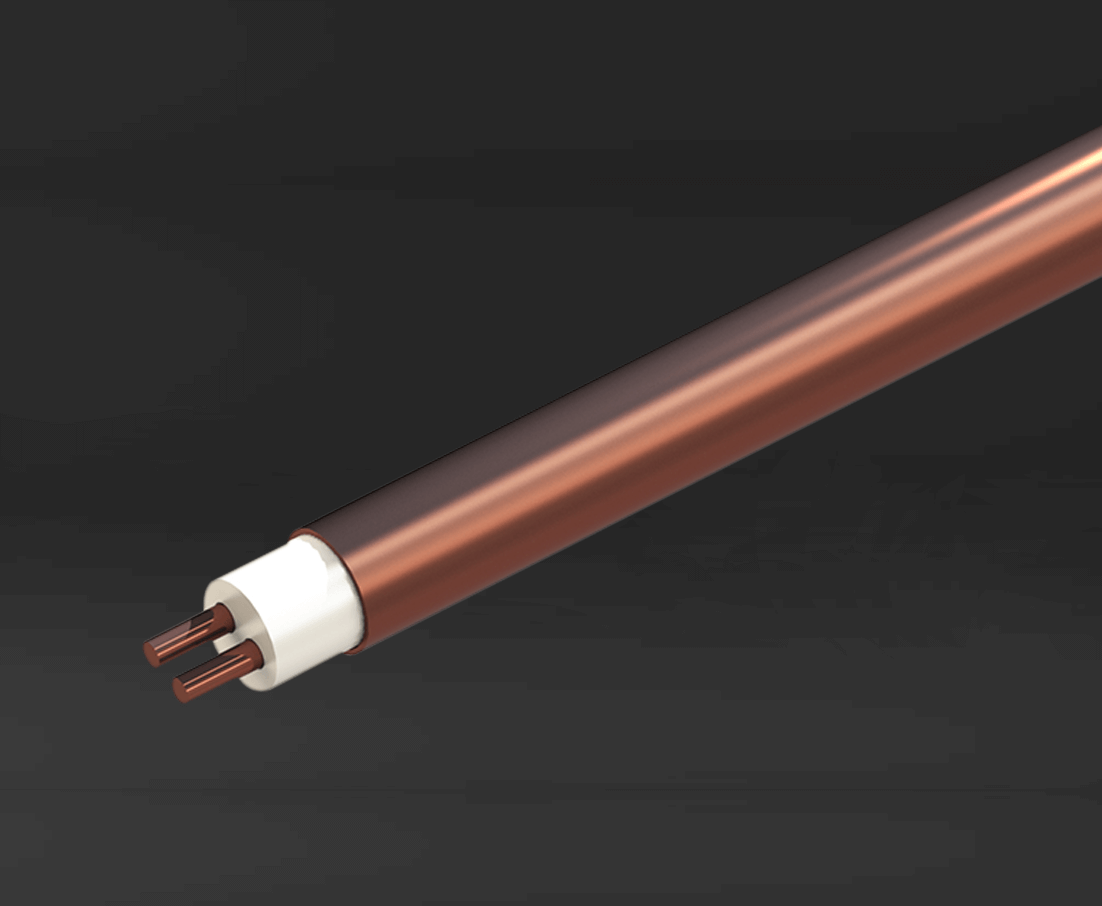

One or more wire-like conductors (cores) are embedded in a high insulation quality MGO and pressed into a metal tube (sheath) made of oxidation and corrosion-resistant material. The entire combination is then processed using suitable forming steps to obtain the final dimensions. Due to good Flexibility, Excellent mechanical strength, and pressure resistance, mineral insulated Thermocouples/ RTDs can be installed in complex installations.

Features of MI Cables

-

- Mechanical Strength: The High Mechanical Strength of MI cables can be attributed to the compact structure of MI Cables consisting of densely packed insulation material MgO with a tough metal sheath that firmly places the conductors in the compound. The bending radius is 3 to 5 times the outer diameter.

- Long Life: The manufacturing of MI Cables is such that it ensures long conductor life as the sheath and insulation present in the MI Cable help the wire stand against harsh environmental conditions. This helps in accurate calibration.

- Corrosion and Scaling Resistance: MI Cable manufactured in our facility are corrosion and scaling resistant, so they can withstand harsh or unfavorable environmental conditions.

- Long Length: We provide long lengths of MI Cable which were not available in the past.

- Quick Response: Quick heat transfer takes place in the MI Cable due to high thermal conductivity and small mass, which assures a fast and speedy response.

- Radiation Resistance: The Radiation Resistance feature of MI Cables is a boon in an application that involves high radiation. These are widely used in the primary circuits and inside the core in the reactors.

- Safety: The MI Cables are highly fire-resistant due to the use of insulation materials such as MgO. These cables are highly recommended from a safety point of view.

- Moisture/Pressure: The homogeneity in the metal sheath helps the cable to tolerate high external pressure by not allowing the flow of the majority of liquid and gaseous particles.

Mineral Insulated Thermocouple Cable

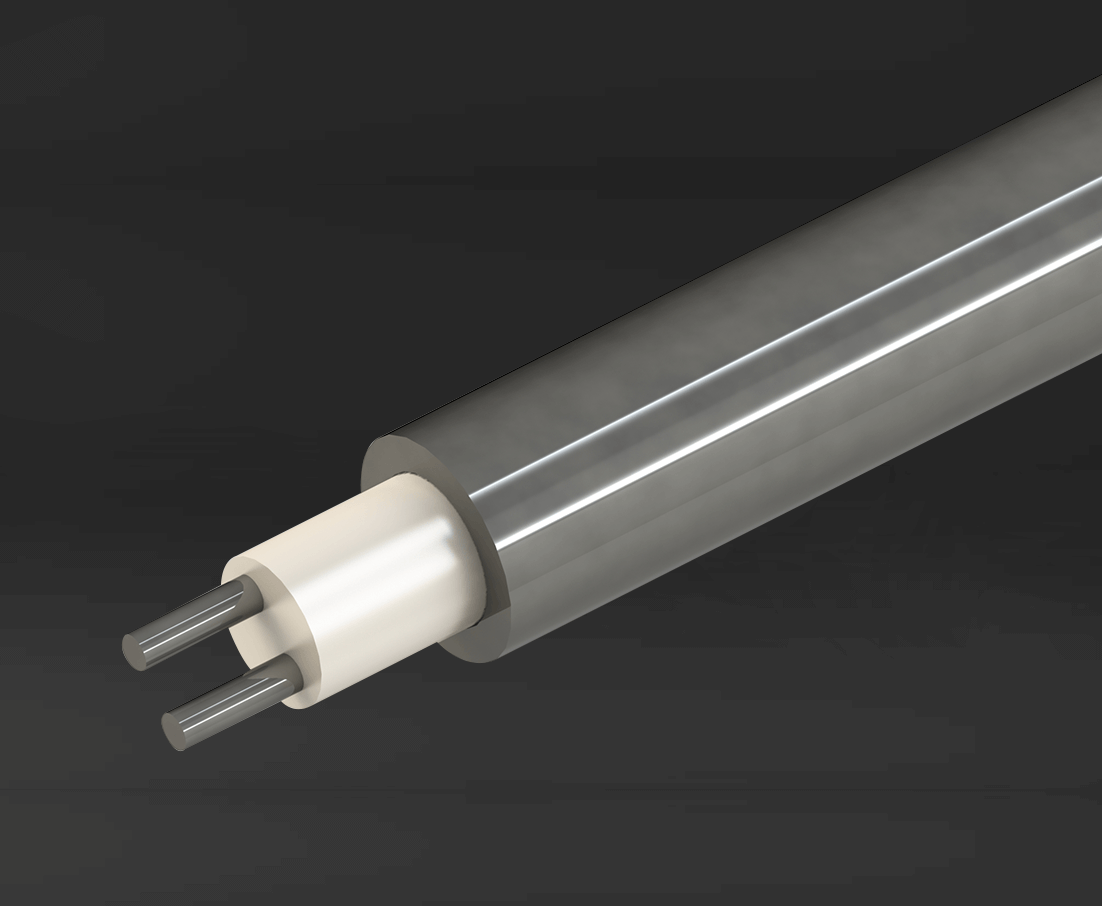

Mineral insulated thermocouple cables have inner conductors of Thermocouple base material as per Standard ASTM E 585/585M and ASTM E 839.

Mineral Insulated RTD Cables

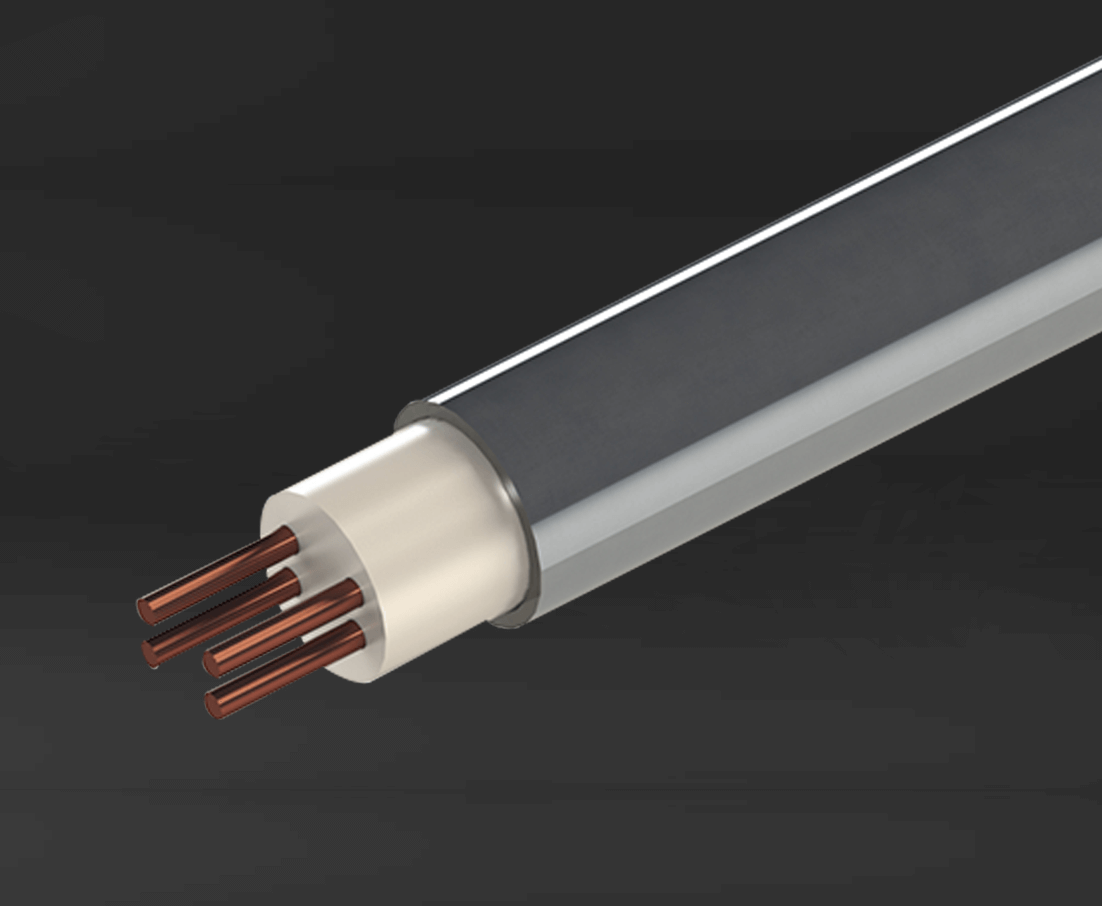

Mineral insulated cables for RTDs have inner conductors of copper, copper-nickel alloys, nickel etc. metals.

Mineral Insulated Heating Cable

Mineral Insulated Heating Cables are constructed with a solid resistor element embedded in highly compacted mineral insulation. MI cables are built to handle high temperature, high wattage applications.

Mineral Insulated Copper Cable (MI Power Cable)

Mineral Insulated Copper cable is used as an electric cable for critical areas of plant and follows standard of IEC/EN 60702 Part 1. It has two voltage grade 500V & 750V.

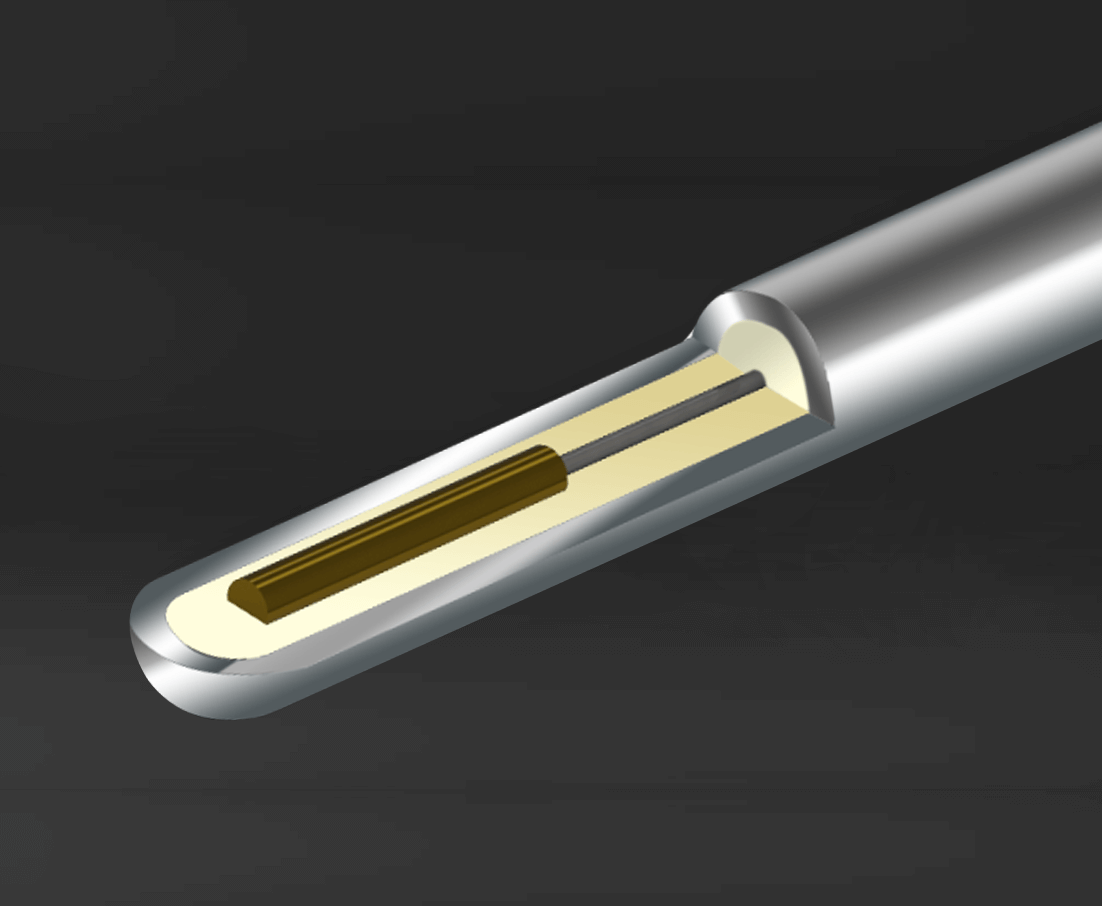

Coaxial / Triaxial Cables

Triaxial cable is a type of electrical cable similar to coaxial cable, but with the addition of an extra layer of insulation and a second conducting sheath. It Provides Greater bandwidth and rejection of interference than coax.

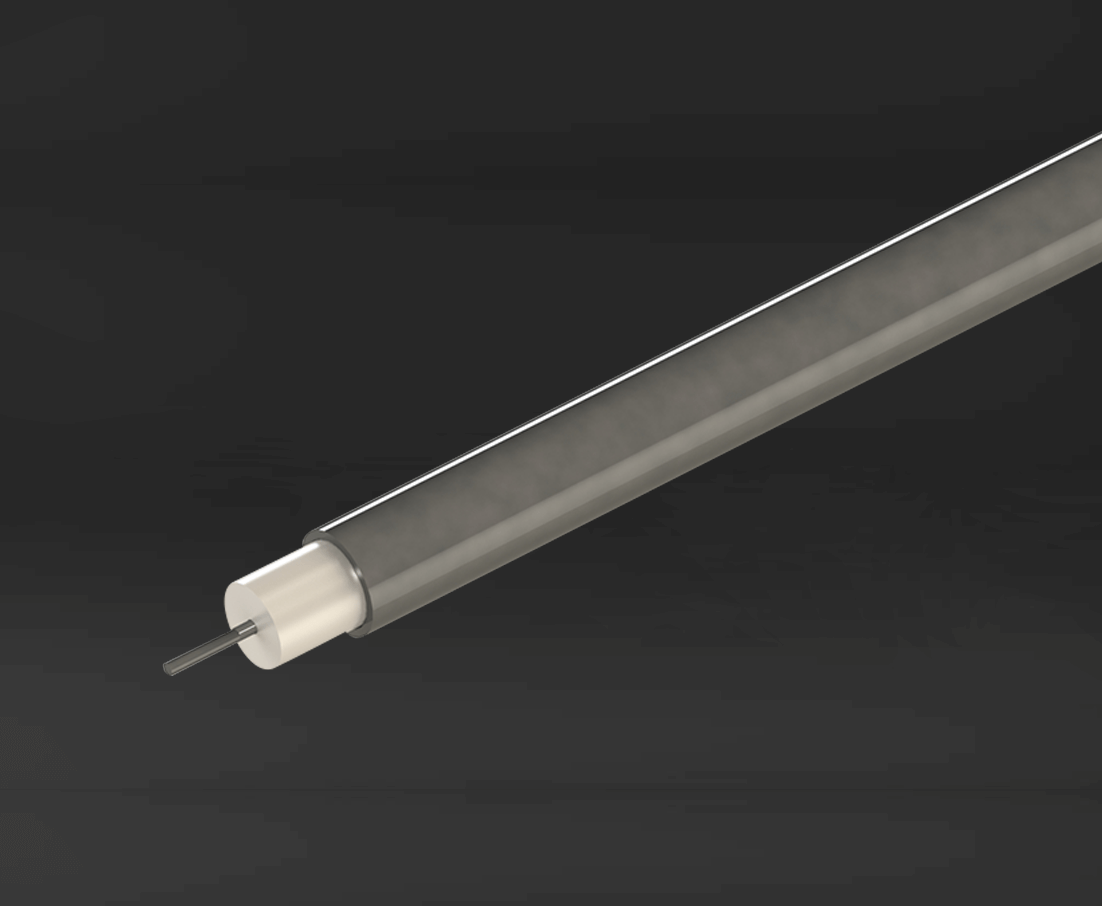

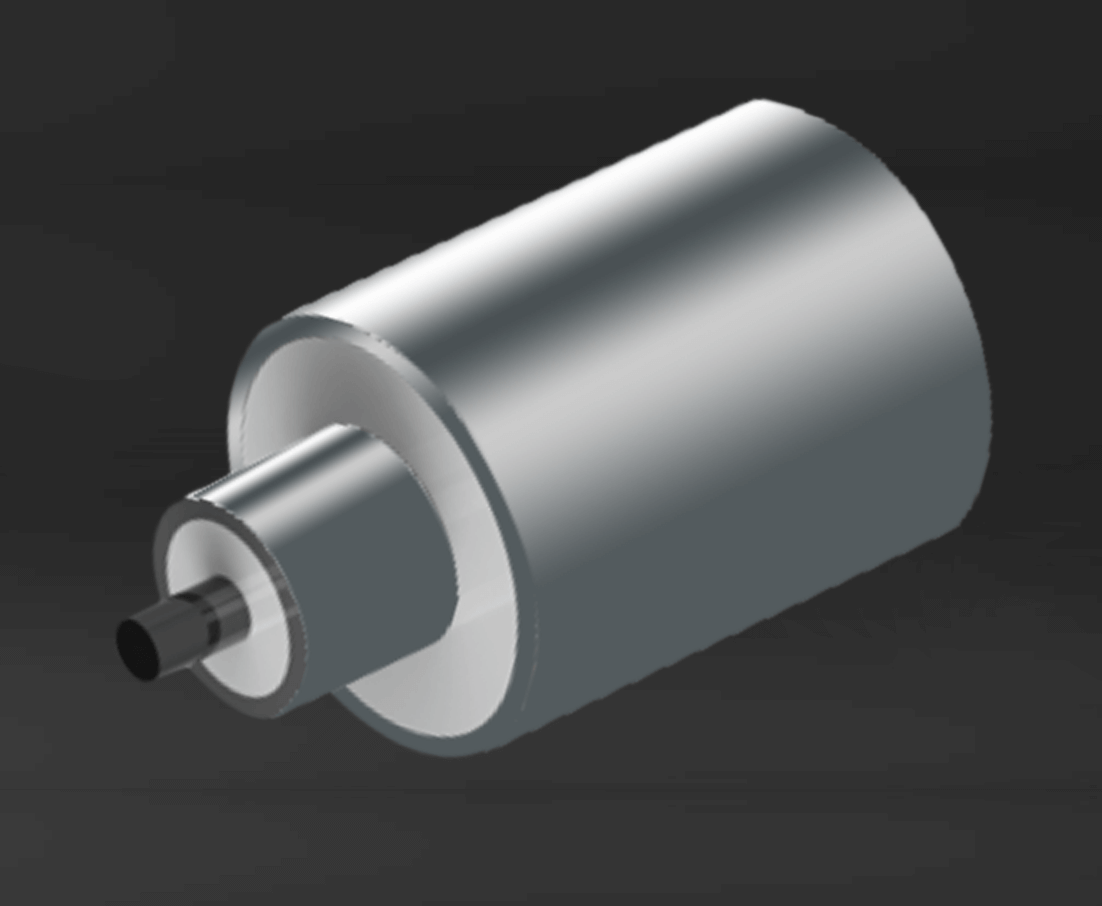

SPNDS (Self Powered Neutron Detectors)

Self-Powered Neutron Detectors are effectively as incoreflux monitors in nuclear power reactors.The typical SPND is a coaxial cable consisting of an inner Electrode (the emitter), surrounded by insulation and an outer electrode (the collector).