- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Powder coatings have a four-stage fundamental curing process (cure schedule):

- Melt the powder.

- Flow out the powder.

- Crosslink and cure the powder.

- Achieve adequate crosslinking.

Temperature, time at temperature, and, in some situations, the pace of temperature change all have a significant impact on these stages. These phases govern the majority of powder coating final qualities and are hence temperature sensitive. The disadvantage of the conventional approach of temperature monitoring of paint ovens and other furnaces is that the product temperature is approximated from the oven temperature. Thus, the impacts of the variables such as track speed, substrate thickness, and thermal uniformity of the oven on component heating rate are ignored.

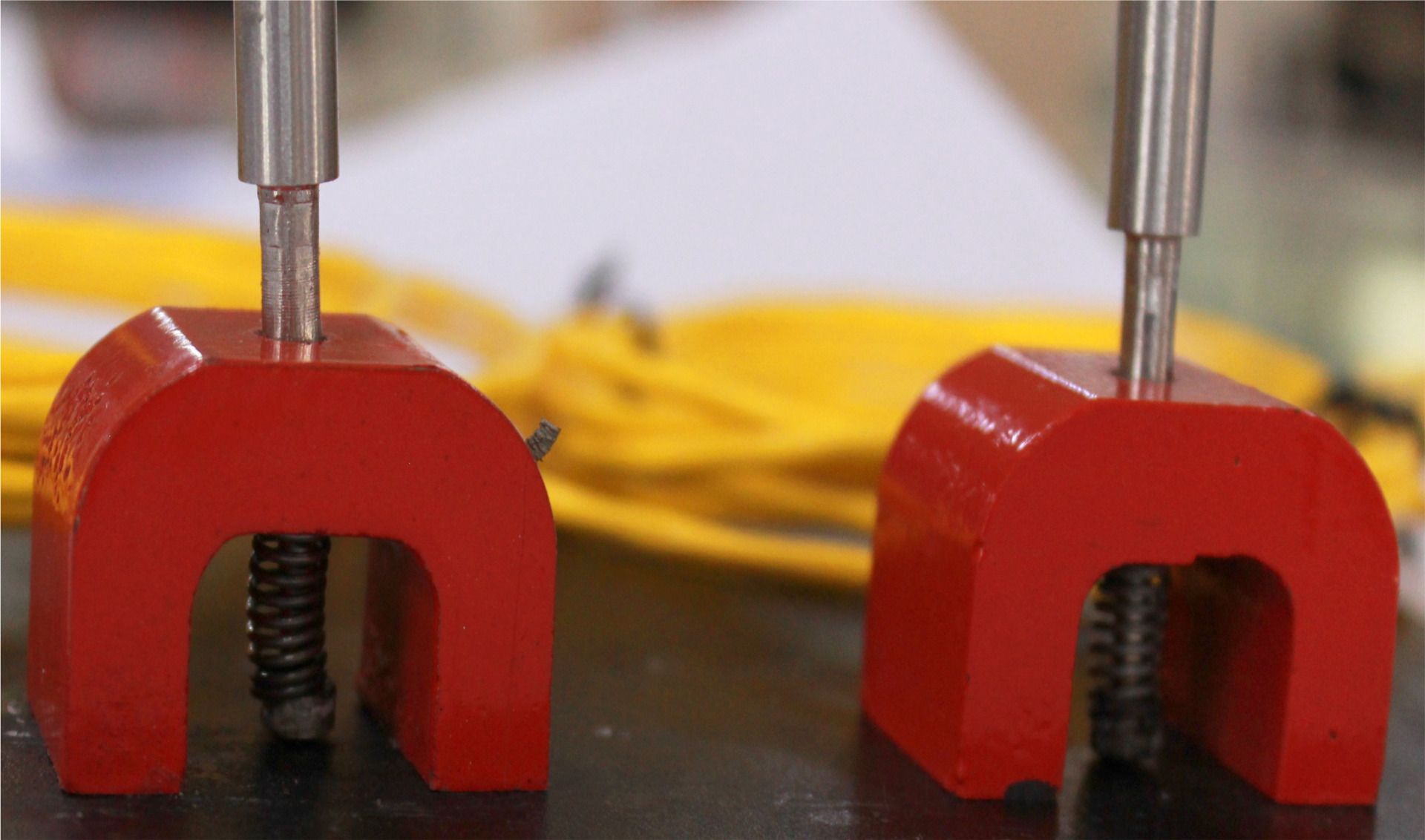

These types of issues can be resolved by measuring the temperature profiling of the product via a suitable thermal profiling system developed by Tempsens instruments Pvt. Ltd.

- Maximum temperature can be reached upto 950°C.

- Stainless steel casing(SS310) which provides resistance to oxidation at high temperatures.

- Smartrack 10 can store upto 50,000 data per channel.

- Provision of rechargeable& non rechargeable batteries according to customer need and temperature range.

- Paint and powder coating suppliers.

- High temperature coating.

- Automotive assembly (OEM)/ BIW.

- Reflow Ovens for soldering & various processes.

- Aluminium powder coatings.

- Metal Packaging.

- Oven suppliers.

- Textile and wood coatings.

Customer Benefits

- Quality: Demonstrate that your oven has the right cure schedule for the physical and aesthetic attributes you need.Prevent downtime, costly rejections or redo, and product recalls by avoiding under cure or over cure difficulties.

- Validation: Generate a profile report to demonstrate that your process is under control to any customer or regulatory agency. The one-page report has the potential to land you the next project.

- Optimization: Increase line speed to increase output without jeopardizing product quality. Make modifications to the oven's temperature set-points to save energy. Consider how much money you may save on electricity over a long run!