- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

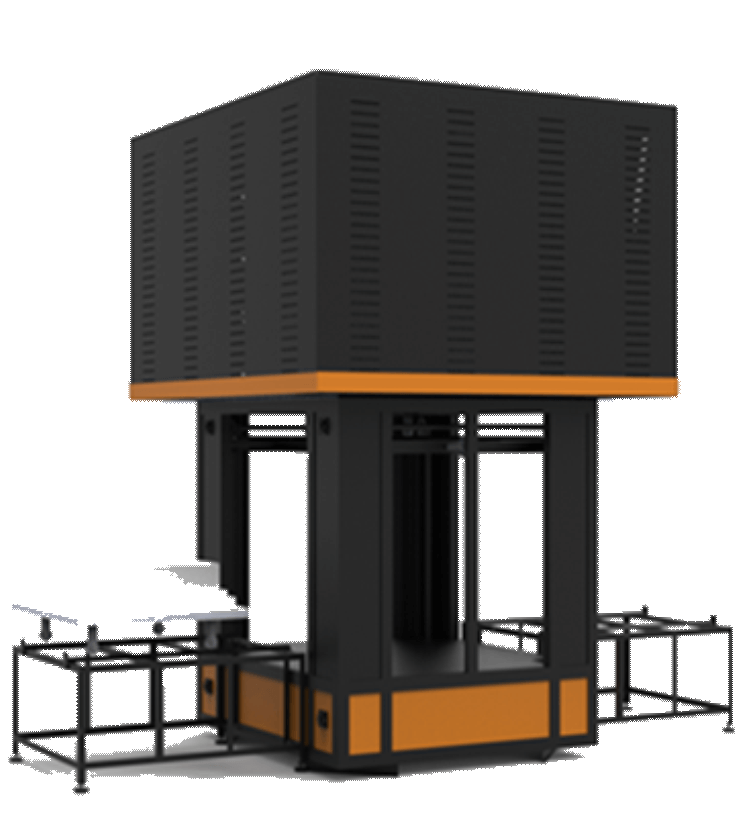

Annealing Furnace

Annealing Furnace

Annealing is commonly used to relieve internal stresses that may lead to failure in service and to produce a more uniform, homogeneous, internal structure. Annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling.

STAGES

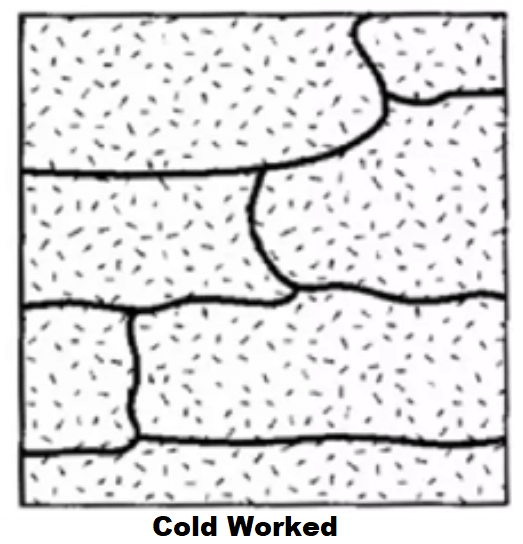

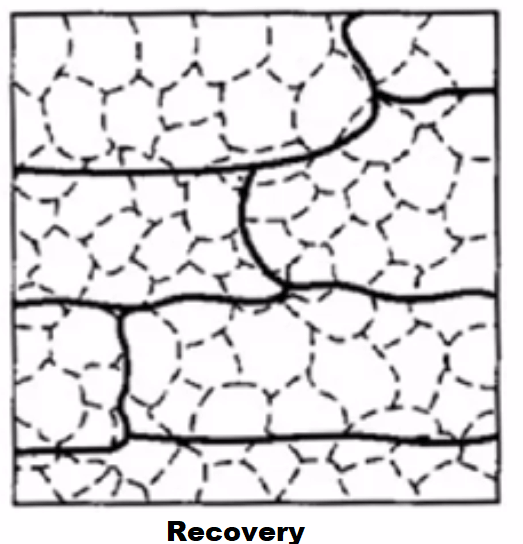

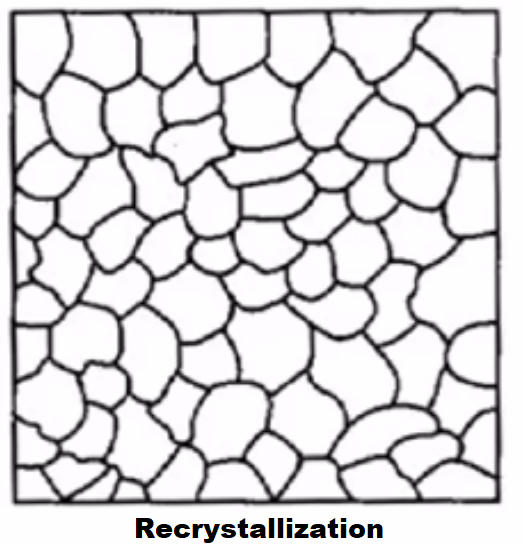

The three stages of the annealing process that proceed as the temperature of the material is increased are: Recovery, Recrystallization, and Grain growth.

- Recovery : Recovery occurs at the lower temperature stage of all annealing processes and before the appearance of new strain-free grains. It results in softening of the metal through removal of primarily linear defects called dislocations and the internal stresses they cause. The grain size and shape do not change .

- Recrystallization : where new strain-free grains nucleate and grow to replace those deformed by internal stresses. If annealing is allowed to continue once recrystallization has completed, then grain growth (the third stage) occurs.

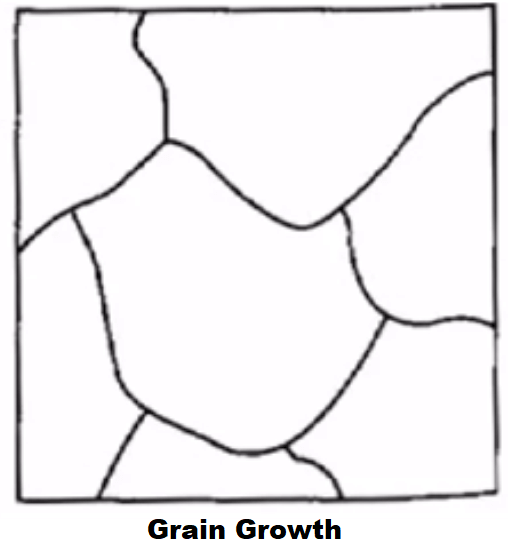

- Grain growth : Grain growth only occurs once the recrystallization has finished and if annealing is allowed to continue. During grain growth, the microstructure of the material starts to coarsen, and the material can lose some strength, so further heat treatment would be required.

HOW DOES AN ANNEALING FURNACE WORK ?

An annealing furnace works by heating the material above the recrystallization temperature, it is made more ductile and therefore ready to be worked once more. Basically Annealing Furnaces and ovens used to change a material's strength and hardness, relieve internal stresses, and provide increased ductility.

Annealing improves the machinability and mechanical or electrical properties of the treated material. Hot rolled steel is also shaped and formed by heating it above the recrystallization temperature. While steel and alloy steel annealing is common, other metals can also benefit from the process, such as aluminium, brass, and copper.

ANNEALING FURNACES FROM TEMPSENS

Annealing furnaces are designed for the processing of SS or Copper wire, rod, strand, strip and tube products. These furnaces are ideally suited for copper, copper alloy, nickel, nickel chrome, titanium, stainless steel and refractory metals. The annealing process may vary based on the material being treated and the desired outcome. Tempsens supply a wide range of industrial furnaces and ovens that able to perform various different heat treatment processes including annealing. Our annealing furnaces can be employed for various materials, and we can also build custom furnaces suited to do any annealing operation including final, full, intermediate, partial, and recrystallization annealing, in varying time and temperature ranges.

STANDARD FEATURES

- Maximum Temperature up to 1800°C.

- High Uniformity up to +/-5°C.

- Multisegment Microprocessor Based Programmable Temperature Controller.

- High quality silicon carbide elements for 1400 °C and molybdenum disilicide heating elements 1400°C to 1800°C Temperature Range

- Individual burner flame safety.

- Provision of gas inlet/outlet.

- Provision for gas/vacuum purging application(Ar, N2, O2, H2, CO2 etc.).

- Over-temperature protection.

- Programmable PID Controller with RS-232/RS485/Ethernet & Data Logging Software.

Why to choose TEMPSENS Annealing Furnace ?

- Provides a compact design thus save floor space

- Able to deliver more uniform process heat

- Highly reliable automatic process control systems

- Ease of operation and maintenance

- Convenient for heavy, large, or high-volume workloads.

For More Details visit us at -Annealing Furnace - AF

Call - +91-9024744551 Or Email - hardik@tempsens.com