- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Tube Furnace

What is Tube Furnace??

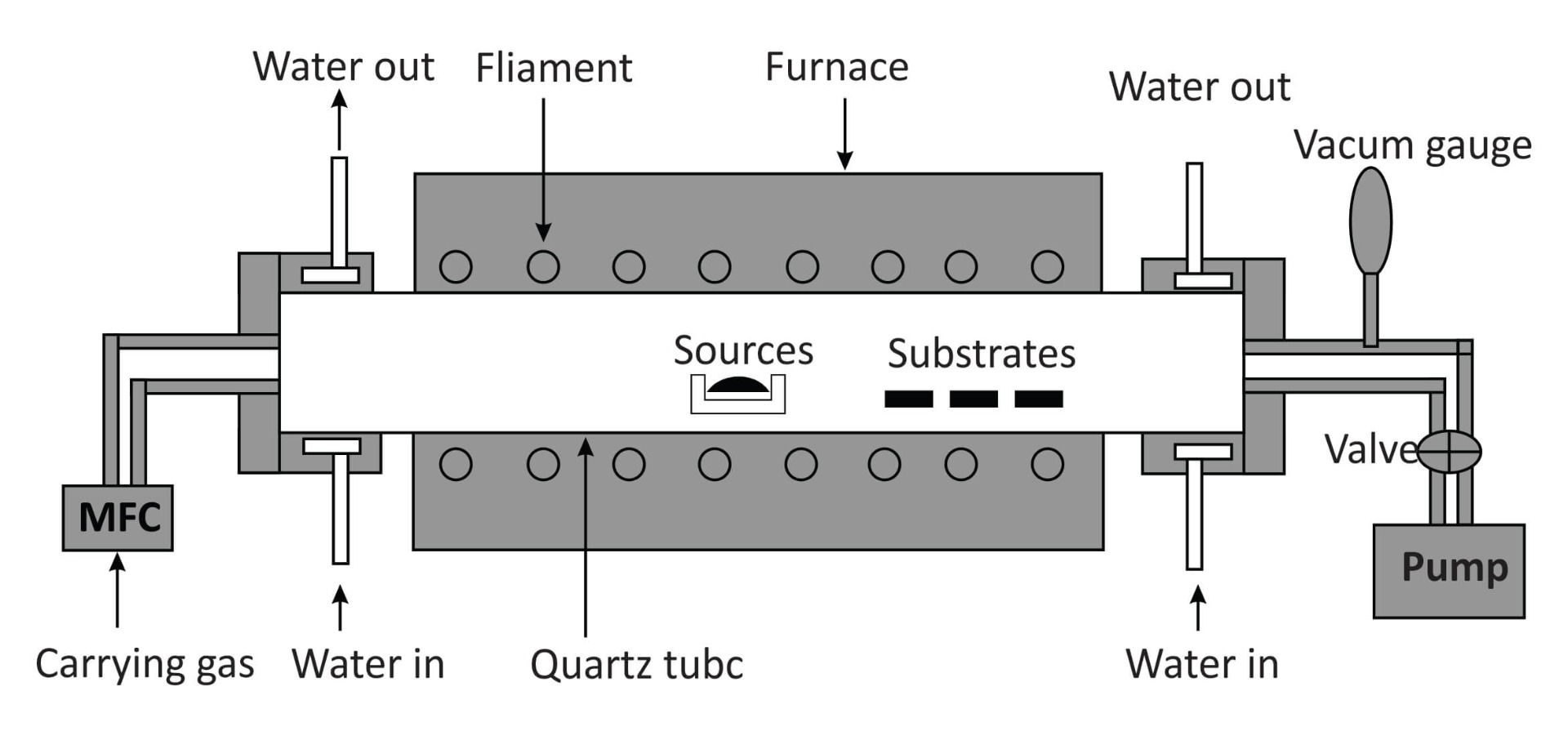

A Tube Furnace is an electric heating device. It generally has a cylindrical tube that is heated by surrounding heating elements. Alumina, fused quartz, and Pyrex are commonly used as tube materials in tube furnaces. Tungsten or molybdenum tubes are used in the case of corrosive materials.

Insulation is used outside to minimize the heat transfer to the environment. It can have single or multiple heating zones as per the requirements of the process or customer. The temperature can be measured and controlled using a thermocouple and controller feedback system.

Why Tube furnace is used?

The main reason behind the use of a tube furnace is the uniformity achieved in a cylindrical tube. A tube furnace with multiple zones controlled individually can have better uniformity over the whole length. Multi-zone Tube Furnace can give a well-defined temperature gradient.

Application

Tube Furnaces are used for a wide range of processes including ageing, annealing, coating, drying, hardening, calcinations, degassing, sintering, soldering, tempering, etc.

A tube furnace can be used to perform syntheses and purification of inorganic compounds. Occasionally it is also used for organic synthesis. Synthesis is an artificially carried out chemical reaction to acquire one or more products. Tube Furnace can be used to break down organic or inorganic compounds into a simpler form by use of heat (thermal decomposition). Tube furnaces are also used for thermocouple calibration.

Types of Tube Furnace

According to the orientation of the tube

- Horizontal Tube Furnace

- Vertical Tube Furnace

According to the tube shape

- Solid Tube Furnace

- Split Tube Furnace

Tempsens make Tube Furnace

Tempsens is a leading manufacturer of high-quality Indigenous furnaces. We offer a single-zone and multi-zone Tube furnace with single and multiple controllers. Tube furnaces can be manufactured in a horizontal tube or vertical tube. We provide solid or split tubes in each of our standard models.

Tube material can be high Alumina/Quartz/Pyrex depending upon the Model. Tempsens tube furnaces provide exceptional temperature uniformity is best for heating small samples. Safety controller for over-temperature protection and other safety features are included as per customer requirements. PID controllers, loggers, and programmers are used as per customer requirements.

- Provision for gas/vacuum purging Application (Ar, N2, O2, H2, CO, etc.).

- Programmable PID controller with RS-232/RS-485/Ethernet & Datalogger software.

| Model | MAX TEMP (C) | POWER (KW) | Heating Element |

| TF – 1200 | 1200 | 2.8 | FeCrAl |

| TF – 1400 | 1400 | 3.5 | Silicon Carbide |

| TF – 1600 | 1600 | 4.0 | MoSi2 |

| TF - 1800 | 1800 | 4.0 | MoSi2 |

BENEFITS

- Energy-saving design

- Fast heat up & cool down

- Exceptional temperature uniformity

- Cold exterior surface

- Designed for longevity

- Economical price

For more details visit at - Tubular Furnace - TF