- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

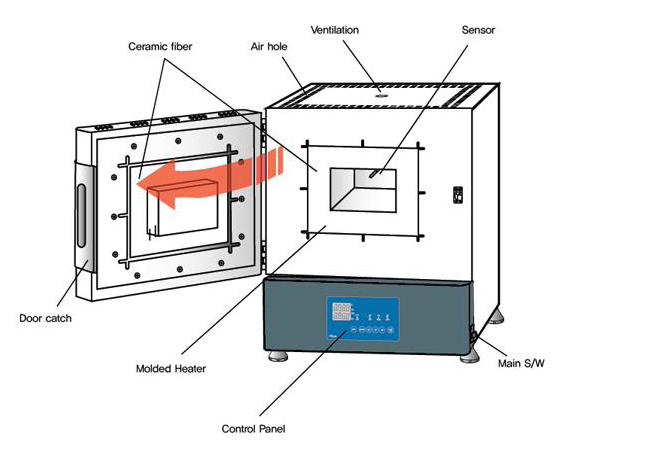

Muffle Furnace

What is Muffle Furnace??

Muffle Furnace is closed chamber type heat treatment equipment that is used to heat a material to high temperature while the material is isolated from the external contaminants, chemicals. Muffle furnace is generally lined with stainless steel, making them resistant to corrosion. Muffle furnaces can attain and maintain temperature up to 1200 °C.

Why Muffle Furnace is used??

The Distinguishing Feature of a muffle furnace is that it separates the material from all the byproducts of combustion from the heat source. In the electric furnace, it means heat is applied to a chamber through induction or convection by a high temperature heating coil inside an insulating material.

Application of Muffle Furnace

Muffle furnace is used for soldering and brazing, technical ceramics, melting glass, creating enamel coatings. They are also used for more sophisticated applications like sintering, debinding, metal injection molding. Testing, coal analysis, annealing, lime calcination are some of their most common uses. These laboratory furnaces are commonly used in physics labs, rice labs, steel and paint businesses, biotech firms, and small industrial operations, among other places.

Other applications of Muffle furnace include ignition testing, heat treatment of steel parts and gears, chemical analysis, tensile strength test, gravimetric analysis, quenching test, stoneware samples firing, estimating proportions of non combustible and non-volatile, etc.

Types of Muffle furnace

1. Box-type Muffle furnace

2. Well type Muffle furnace

3. Atmosphere Muffle furnace

Muffle Furnaces by Tempsens

Tempsens is a leading manufacturer of high-quality Indigenous furnaces. We provide muffle furnaces up to the maximum temperature of 1800 C. we offer

muffle furnaces in standard models. These muffle furnaces can be custom designed and built to suit the needs of the customer.

These Tempsens make MF is having a robust structure with greater durability, are versatile in application, and are designed for easier operation and maintenance. We at Tempsens believe in using the best quality material and equipment for the manufacturing of furnaces. These furnaces are reliable in operation and have a long life.

| Model | Volume(liters) | Power(KW) | Heating element |

| MF 112 | 1.5 | 2.0 | FeCrAl |

| MF 312 | 5 | 2.8 | FeCrAl/APM |

| MF 412 | 7.9 | 3.2 | FeCrAl/APM |

| MF 512 | 18.5 | 8.0 | FeCrAl/APM |

Standard Features

- Door limit switch

- Silicon Carbide Muffle

- Thermocouple break protection

- Solid-state relay for low noise operation

- Safety controller for overheat protection

Optional Features

- Provision for gas/Vacuum purging

- Programmable PID controller with RS-232/RS-485/Ethernet

- Data logger software

Advantages

- Energy-efficient design

- Fast heat up & cool down

- Exception temperature accuracy

- Exceptional temperature uniformity

- Best temperature and process control

- Cold exterior surface

- Designed for longevity

- Economical price

For more details visit: Muffle Furnace