- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Automatic Dental Porcelain Furnaces

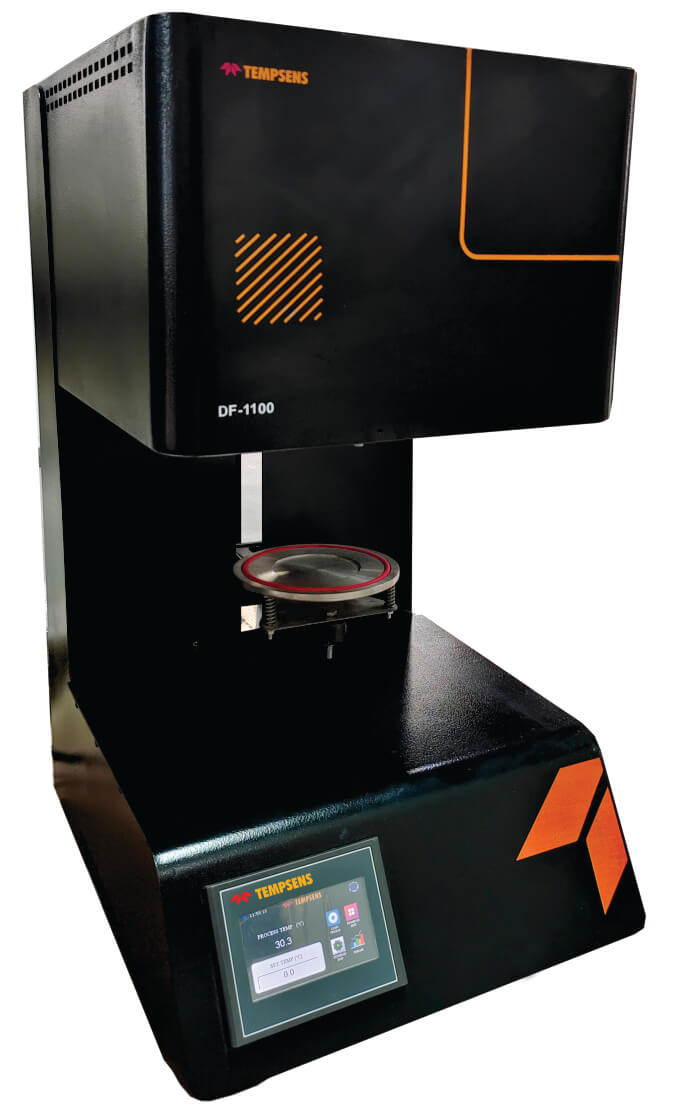

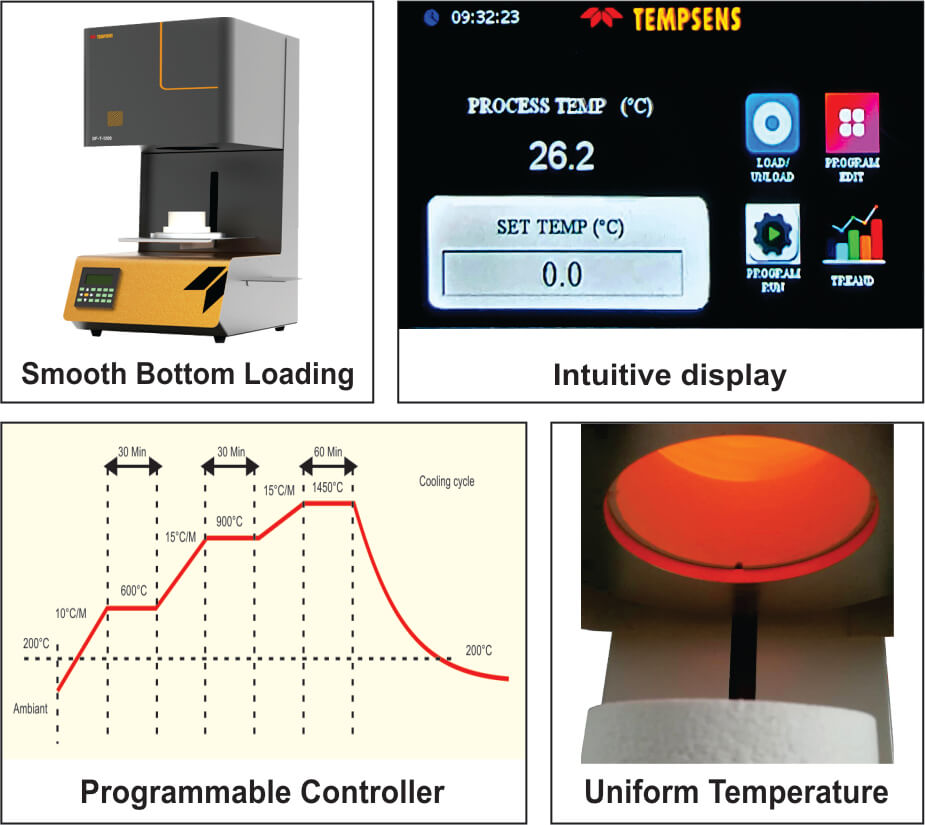

Dental Porcelain Furnaces are suitable for the manufacturing of metal-ceramic and all-ceramic restorations for use in dentistry such as dental crowns, bridges. All Tempsens make Dental Furnace comes with touchscreen colour Display and Multisegment programmable controller.

These furnaces are particularly used for firing or sintering of dental opaques, dentine and enamel materials to the respective compatible substructure materials.

These are also used for other applications such as oxidizing metallic substructures in preparation for porcelain firing, melting pressable ceramics, stain and glaze firing, etc.

Tempsens covers all types dental furnaces range like ceramic furnaces, sintering furnaces and ceramic combination furnaces

Ceramic Furnace:

This basic version of dental furnace is used during different ceramic dental restorations jobs like crowns, bridges, inlays and onlays. These furnace employ high temperatures and pressure to process ceramic materials into a hardened, Final sate. Sometime ceramic furnaces used with both CAD/CAM milled restorations as well as with glaze systems that add a final aesthetic polish. We provide all types customised solution to work with wide ranges of various ceramic materials. The typical temperature ranges for these furnaces from 100⁰C to 1200⁰C

Dental Ceramic Combination Furnaces :

The basic function of these furnace is to employ combination of temperature and pressure to press ceramic materials into the proper restoration design. So these furnaces are designed for both firing ceramic restorations and for pressing ceramics. These furnaces include programs for firing for different types of ceramic materials as well as featured to create suitable customised programs to meet the need of any customer.

Sintering Furnaces :

Basically these furnaces made for Higher temperature application and capable of reaching extremely high temperatures required to sinter zirconia to its final hardness. These furnaces are used to process dental zirconia after it has been milled into a crown, bridge, framework or other restoration. During the sintering process which can involve pressure as well as heat, reduces the porosity and increases the density of ceramic materials such as zirconia. The typical temperature ranges of these furnaces up to 1600⁰C

Features:

- Uniform Heating Zone

- Multisegment Programmable Controller

- 4.5” Colour Touch Screen Display

- Precise motorized Tray movement that allows lifted or lowered with a smooth motor drive mechanism

- Maximum Temperature offered up to 1200⁰C (Optional 1600⁰C).

- Over temperature, Over current protection

- Maximum vacuum 980 mBar

- RS 232/RS 485 Communication for Remote connection with USB for Temperature Data storage and logging.

Why to Choose Tempsens Furnaces

- Provides a compact design thus save floor space.

- Able to deliver more uniform process heat.

- Easy loading and unloading.

- Highly reliable automatic process control systems.

- Ease of operation and maintenance.

- Convenient for heavy, large, or high-volume workloads.

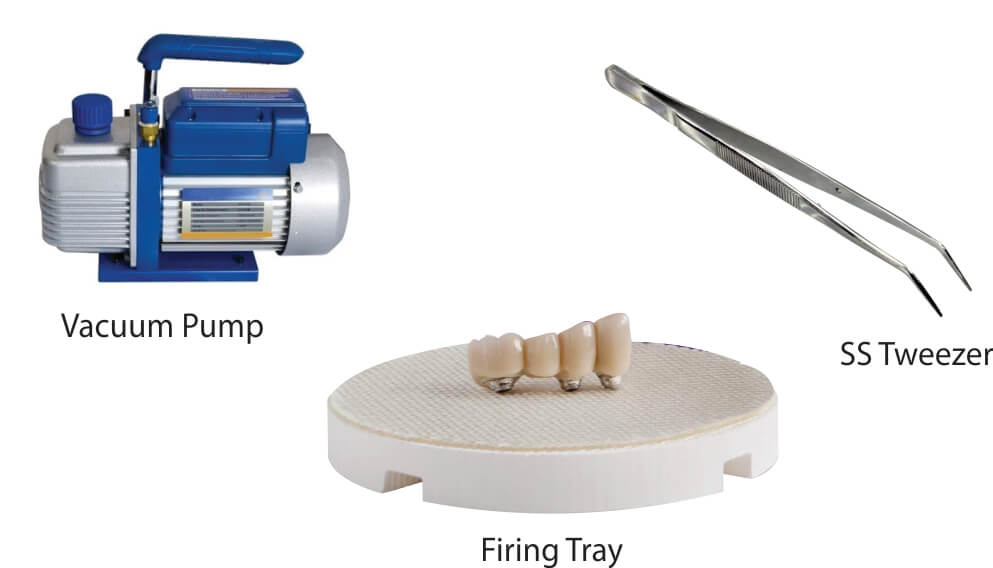

- Comes with Sintering tray, SS tweezers, pliers & vacuum pump.