- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Conveyor Belt Furnace For Quartz Material Heat Treatment

Quartz is a versatile mineral widely used in various industries, including electronics, optics, semiconductor manufacturing, and solar cell production. Heat treatment of quartz material is a very important process that involves subjecting quartz, a mineral composed of silicon and oxygen, to controlled heating under specific conditions. This treatment can bring about various changes in the physical, chemical, and optical properties of the quartz material.

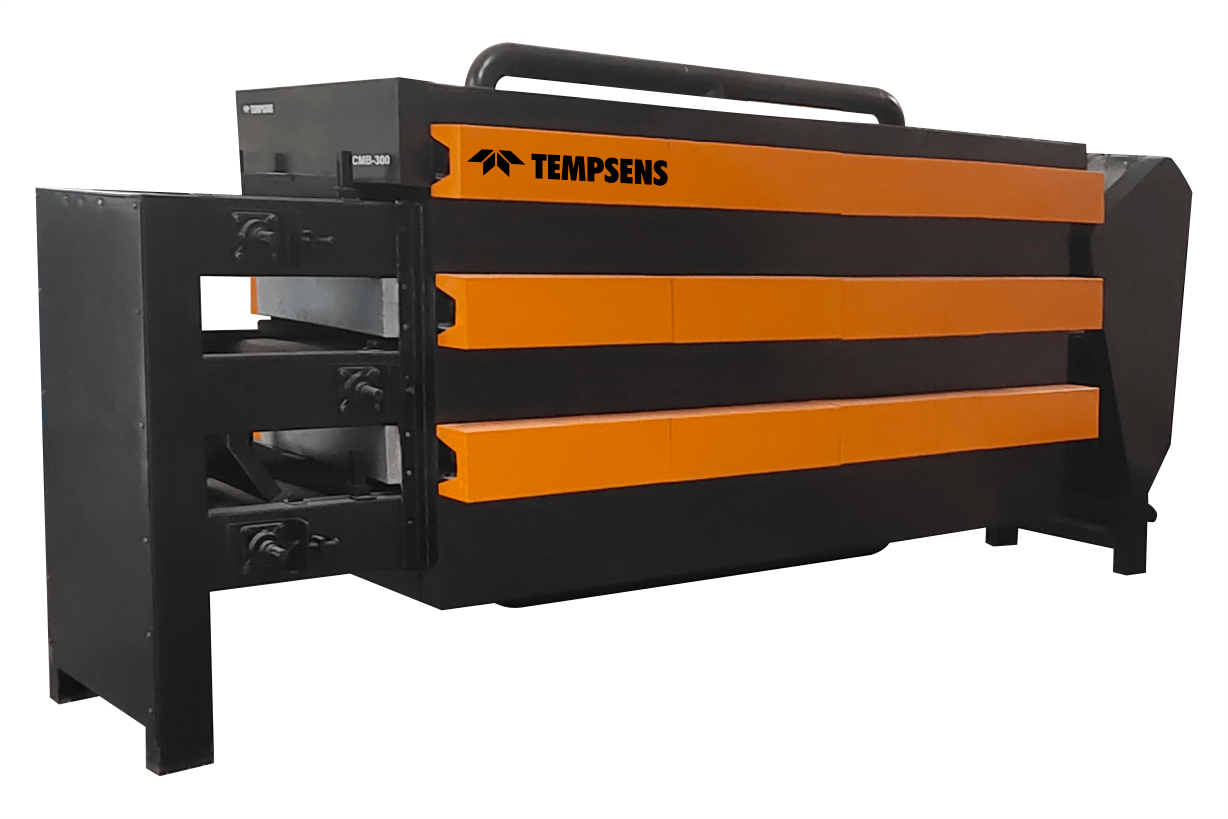

Tempsens makes a Conveyor Mesh Belt Furnace specially designed to process quartz-based materials using a continuous conveyor belt system for quartz material treatment. The number of controlled Heating and cooling zone, length of the zone, belt width, Cabinet size, and Movement speed can vary based on the specific requirements of the materials and processes involved, contributing to the production of high-quality components and products in various fields.

How A Conveyor Belt Furnace For Quartz Material Treatment Work?

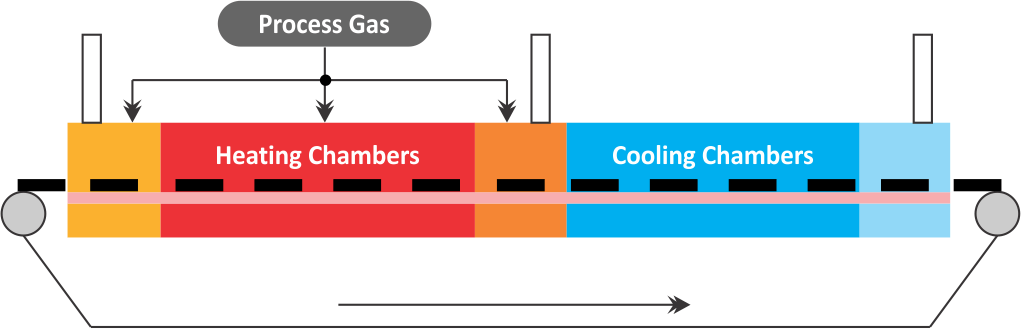

- Loading Zone: Raw quartz material is loaded onto the conveyor belt at the entrance of the furnace. The conveyor system is designed to ensure a continuous and controlled flow of materials through the furnace.

- Heating Zone: The conveyor belt moves the quartz materials through the heating zone of the furnace. Inside this zone, the materials are exposed to carefully controlled temperature profiles. Heating quartz materials can lead to various outcomes, such as crystallization, stress relief, annealing, or transformation of certain properties.

- Cooling Zone: After passing through the heating zone, the materials move into the cooling zone. This zone gradually reduces the temperature of the materials to a level suitable for handling and further processing.

- Process Monitoring and Control : Tempsens make Conveyor belt furnaces include Highly accurate sensors and advanced control systems. These systems monitor and regulate temperature, atmosphere, and conveyor speed.

- Atmosphere Control: Inert gases or specific gas mixtures (Ar, N2, O2, H2, CO2 etc.) can be introduced to prevent oxidation or control reactions occurring during heating and cooling.

- Unloading Zone: Once the materials have completed the treatment process, they are unloaded from the conveyor belt. At this point, they may be further processed, inspected, or packaged for their intended application.

Why Tempsens Make Conveyor Belt Furnace:

- Continuous Processing: The conveyor system allows for a continuous flow of workpieces, ensuring consistent and efficient processing.

- Uniform Heat Treatment: Uniform Heat treatment of quartz material is very important. The mesh belt evenly supports the workpieces, promoting uniform heat distribution and treatment.

- Reduced Labour: These furnaces are often automated, reducing the need for manual labour and increasing productivity. Automation decreases the need for constant monitoring and handling by workers.

- Precise Control: The furnace can be controlled with precision, maintaining accurate temperatures and heat treatment profiles. Advanced Multisegment Programmable PID Controller with RS-232/RS485/Ethernet for Remote operation & Data Logging Software.

- Efficiency: The continuous conveyor system allows for efficient processing of large quantities of items in a relatively short period thus contribute to energy saving as well.

- Consistency: The controlled environment and uniform conveyor movement lead to consistent curing or drying results across all quartz items.

- Space-Saving: These furnaces have a compact design, making them suitable for facilities with limited space.

- Customization: Furnace parameters such as temperature, conveyor speed, and heating time can often be adjusted to suit specific curing or drying requirements of different types of quartz material.

Conveyor Belt Furnace for Various Quartz Material Heat Treatment:

- Annealing: Quartz is often subjected to annealing to remove strain caused during manufacturing processes and enhance its thermal stability and improve the mechanical stability.

- Crystalline Transformations: Depending on the temperature and duration of heat treatment, quartz can undergo structural changes.For instance, it can transform from its alpha form to beta form (and vice versa) at specific temperatures. These changes can influence its properties, such as thermal expansion coefficient and mechanical strength.

- Colour Alteration: Heat treatment can cause color changes in quartz. For example, amethyst (a purple varietyof quartz) can turn yellow or colorless when exposed to high temperatures. This color alteration is due to the presence of trace elements within the quartz lattice.

- Enhancement of Optical Properties: Some types of quartz are often

heat-treated to enhance their color and clarity. Heat treatment can improve the color of the quartz by changing the oxidation state of certain trace elements present in the crystal structure.

heat-treated to enhance their color and clarity. Heat treatment can improve the color of the quartz by changing the oxidation state of certain trace elements present in the crystal structure. - Impurity Removal: Heat treatment can be used to remove impurities from quartz material. High temperatures can lead to the vaporization of certain volatile impurities, leaving behind a purer quartz material. Tempsens offer temperature Range up to 300C for curing and drying of different types quartz material.

- Fusion: Quartz materials can be heat-treated to fuse them together, creating a solid, single piece. This technique is often used in the manufacturing of quartz glassware and laboratory equipment

For more details visit at Conveyor Mesh Belt Furnace