- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

HTF Fast Cooling Furnace For Ceramic Industries

High Temperature Furnace (HTF) Fast Cooling Series Furnaces commonly used in Applications such as Heat Treatment, Annealing, Tempering, and Stress Relieving of metals and Alloys, Sintering ceramics, Dental, metallurgical and ceramic laboratories.

A fast cooling furnace, also known as a rapid cooling furnace or quenching furnace, is an industrial heating device used in various manufacturing processes to quickly cool materials after they have been subjected to high temperatures. The primary purpose of fast cooling is to prevent undesired microstructural changes and improve the material's mechanical properties.

This series furnaces specifically designed to get the best result between the heating speed and the operating life of Heating element and the thermal insulation. The combination of preformed ceramic fiber board panels, Refractory bricks, and high quality resistances, blowing cooler ambient air directly into the furnace allow a very rapid rise in temperature and cooling thus having great advantages in the work with batch type material loading.

The Benefits of Automatic Fast Cooling Furnaces:

- Improved Material Properties: Rapid cooling helps in achieving desired material properties such as hardness, strength, and toughness, as it influences the formation of specific microstructures within the material.

- Time and Energy Efficiency: The quick cooling process reduces overall cycle time, which can lead to increased productivity and energy savings.

- Reduced Residual Stresses: Fast cooling can minimize the formation of residual stresses in materials, which can otherwise cause distortion or cracking.

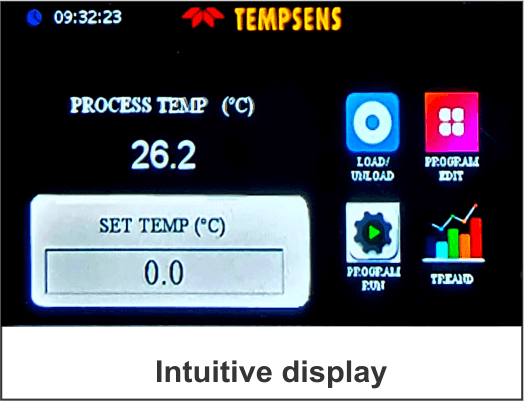

- Precise Control: This fast cooling furnace are equipped with advanced temperature control systems, ensuring accurate and consistent cooling rates.

- Versatility: These furnaces can be used with various materials, including ferrous and non-ferrous metals, to achieve specific material properties.

- Automation and Safety: HTF Fast cooling furnaces are designed with automation features to improve safety and reduce manual intervention.

Features of HTF Fast Cooling Furnace

- Maximum Temperature up to 1300°C.

- Customizable volume.

- Fast Heating and cooling within 30 Min.

- High Uniformity up to +/-5°C.

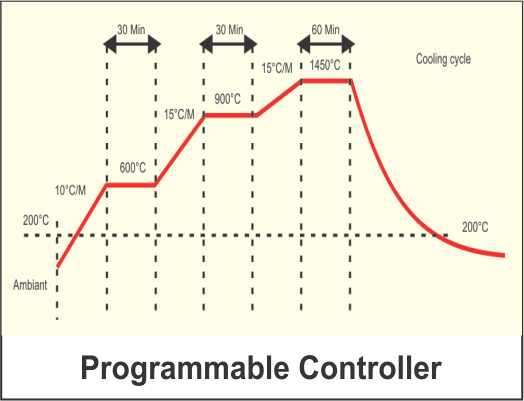

- Multi segment Microprocessor Based Programmable Temperature Controller.

- High quality silicon carbide elements for continuous working up to 1300°C

- Provision of gas inlet/outlet.

- PLC Controlled Programmable Exhaust thus controllable air inlet and outlet.

- Over-temperature protection.

HTF Fast Cooling Furnace for Ceramic Glazing:

Ceramic glaze is a thin layer of glossy or matte material that is applied to the surface of a ceramic piece before firing. The glaze functions as a waterproof barrier to protect the clay beneath and various pigments and opacifiers are often added to produce decorative patterns, textures, and colors. The glaze must be compatible with the clay body and also be suitable for its firing temperature.

The main purpose of fast cooling is to stabilize the microstructure of the ceramic material. When ceramic materials are heated to high temperatures during firing, their crystal structure undergoes changes. Rapid cooling helps prevent the growth of undesirable crystal phases, which could lead to defects or reduced performance in the final Product.

In this series of furnaces, the cooling rate in the fast cooling furnace is carefully controlled to achieve the desired characteristics of the ceramic glaze. Different types of ceramics and glazes require specific cooling rates to obtain optimal properties such as hardness, strength, colour, and surface finish.

Why To Choose Tempsens

- Provides a compact design thus save floor space.

- Able to deliver more uniform process heat.

- Easy loading and unloading.

- Highly reliable automatic process control systems.

- Ease of operation and maintenance.

- Convenient for heavy, large, or high-volume workloads.

For more details visit at High Temperature Furnace