- Home

- About

- Products

- Contact Temperature Sensors

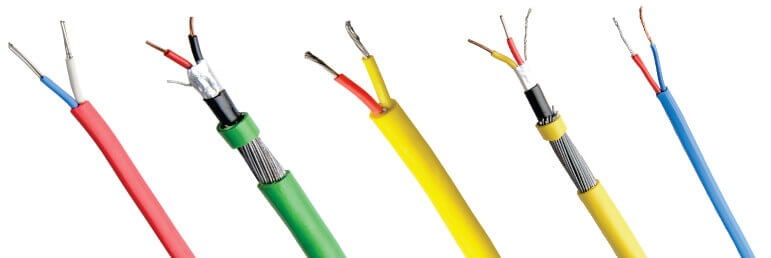

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Understanding Thermocouple Cables: Types, Uses, and Selection Guide

Introduction

Introduction

Thermocouple Cables are used to measure the temperature directly. The thermocouple wire or cable is used to manufacture thermocouple probes in order to sense temperature using the point of cold junction compensation (cjc end).

Thermocouple cables are commonly used in numerous industrial applications, ranging from temperature sensors in gas turbines to laboratory and domestic applications. The extension grade thermocouple wire typically has a lower ambient temperature limit than thermocouple, meaning it may pass a signal representing a higher temperature as received from the probe, but the wire itself may not be physically exposed to higher temperatures.

The Basics of Thermocouple Cables

A thermocouple wire is one which is fitted inside a thermocouple, and usually consists of one positively charged wire and another negatively charged one. For example, the positively charged wire could be copper while the negatively charged one could be nickel. It works when these two wires connect at the temperature measurement junction as that point sparks off a thermoelectric current.

Thermocouple extension cables are paired conductors, with each conductor being made of a different material - Cables' most commonly specific thermocouple is the Type K variety, where the positive conductor is Chromel alloy (abbreviated as NiCr and with green numbered insulation) and the negative is Alumel (NiAl and with white insulation).

Other thermocouple variants are designated EX - NiCr / CuNi (Nickel Chromium / Copper Nickel) with an individual screen, and TX - Cu / Cu/Ni (Copper / Copper Nickel) available as both collective screening (CAM) and individual and collective screened (ICAM) variants and with a double steel tape armour.

Types Of Thermocouple Cables

Different thermocouple types, for the reasons above, require different types of alloy wire combinations. Some of the most popular thermocouple wire and cable types are listed below:

► Type E (Chromel/Constantan)

► Type J (Iron/Constantan)

► Type K (Chromel/Alumel)

► Type T (Copper/Constantan)

Thermocouple extension wire is used to extend the signal from a probe to the required instrumentation, such as controllers or recording devices. Multi pair thermocouple extension cables are preferred for these applications because their accuracy, stability in transmission integrity and the high build quality of thermocouple cables. Extension wires are designated by an 'X' aft the ANSI thermocouple type, such as those listed below:

► BX

► EX

► JX

► KX

► SX

► TX

Industrial And Commercial Uses Of Thermocouple Cables

In the realm of temperature sensing and control, few technologies match the versatility and reliability of thermocouple cables. These robust instruments find extensive utility across a spectrum of industrial and commercial sectors, where precise temperature measurement is paramount. Let's delve into the myriad applications where thermocouple cables play a pivotal role:

- Industrial Process Optimization: From manufacturing plants to chemical refineries, thermocouple cables are indispensable tools for monitoring temperatures in critical processes. Their ability to withstand high temperatures and harsh environments ensures accurate data collection, facilitating optimal process control and efficiency.

- HVAC Systems Management: In commercial buildings and residential spaces alike, Heating, Ventilation, and Air Conditioning (HVAC) systems rely on thermocouple cables for temperature sensing and regulation. By ensuring comfortable indoor environments, these cables contribute to enhanced occupant comfort and energy efficiency.

- Precision in Food Processing: The food industry depends on thermocouple cables to maintain precise temperatures during various stages of food processing, including cooking, chilling, and storage. By upholding strict temperature standards, these cables safeguard food quality and safety, minimizing the risk of contamination or spoilage.

- Medical Equipment and Devices: Thermocouple cables play a crucial role in medical equipment, including thermometers, incubators, and sterilizers. Their accuracy and reliability make them indispensable for monitoring and controlling temperatures in healthcare settings, ensuring optimal patient care and safety.

- Automotive Performance Optimization: Within automotive systems, thermocouple cables are deployed for monitoring temperatures in engines, exhaust systems, and climate control units. By providing real-time temperature data, these cables facilitate engine optimization, emission control, and overall vehicle performance.

- Aerospace Exploration and Innovation: In the aerospace industry, thermocouple cables are utilized in spacecraft, aircraft, and ground support equipment to monitor temperatures in extreme environments. Their resilience to high temperatures and rapid temperature changes makes them ideal for aerospace applications, where precision and reliability are non-negotiable.

- Power Generation and Distribution: Power plants rely on thermocouple cables for monitoring temperatures in boilers, turbines, and electrical components. By detecting temperature variations and potential failures, these cables contribute to the efficient operation of power generation systems, ensuring uninterrupted electricity supply.

- Laboratory Research and Development: In research laboratories, thermocouple cables are instrumental for conducting experiments, analyzing data, and monitoring temperatures in scientific instruments. Their versatility and accuracy make them indispensable tools for researchers across various disciplines.

- Energy Management and Conservation: Thermocouple cables are integrated into energy management systems to monitor temperatures in industrial facilities, commercial buildings, and residential properties. By optimizing energy usage and maintaining comfortable indoor environments, these cables contribute to sustainability and cost savings.

- Safety and Security Enhancement: Thermocouple cables are integral components of fire detection systems, alarm systems, and industrial safety equipment. By continuously monitoring temperatures and detecting potential hazards, these cables enhance safety protocols and mitigate risks in various settings.

Selecting The Right Thermocouple Cable

- Understand Thermocouple Types: Thermocouples come in various types, each with its own temperature range and characteristics. Common types include Type K, Type J, Type T, and Type E, among others. Begin by understanding the temperature range of your application and select a thermocouple type that best suits your needs.

- Evaluate Temperature Range and Accuracy Requirements: Determine the temperature range over which your thermocouple will operate and the required level of accuracy. Different thermocouple types have distinct temperature limits, and selecting the appropriate type ensures accurate temperature measurement within your desired range.

- Assess Environmental Conditions: Consider the environmental conditions in which the thermocouple cable will be deployed. Factors such as exposure to moisture, chemicals, vibration, and electromagnetic interference can impact cable performance. Choose a cable with insulation and protective coatings that are compatible with the environmental conditions of your application.

- Choose Insulation Material Wisely: Thermocouple cables are available with various insulation materials, each offering unique properties such as flexibility, chemical resistance, and temperature tolerance. Common insulation materials include PVC, Teflon, fiberglass, and ceramic. Select an insulation material that can withstand the conditions of your application while providing adequate protection for the thermocouple wires.

- Consider Cable Construction and Flexibility: Evaluate the construction and flexibility of the thermocouple cable, especially if it will be subjected to bending or movement. Choose a cable with appropriate flexibility and durability to withstand the rigors of your application without compromising performance or longevity.

- Balance Cost and Quality: While cost is an important factor, prioritize quality and reliability when selecting a thermocouple cable. Investing in a high-quality cable may incur higher upfront costs but can ultimately lead to savings by reducing maintenance, downtime, and replacement expenses over time.

- Consider Future Expansion and Compatibility: Anticipate future needs and ensure that the selected thermocouple cable is compatible with your existing equipment and systems. Additionally, consider the potential for future expansion or upgrades and choose a cable that allows for scalability and flexibility.

Installation And Maintenance Tips

Installing and maintaining thermocouple cables properly is essential for accurate temperature measurement and prolonged lifespan. Whether you're setting up new equipment or ensuring the smooth operation of existing systems, following best practices for installation and maintenance can significantly enhance performance and reliability. Here are some essential tips to help you navigate the process effectively:

- Plan and Prepare: Before installation, thoroughly plan the placement of thermocouple cables to ensure they are positioned correctly for accurate temperature measurement. Consider factors such as proximity to heat sources, potential sources of interference, and accessibility for maintenance.

- Handle with Care: Treat thermocouple cables with care to avoid damage to the insulation or wire junctions. Avoid bending the cables excessively or applying excessive force during installation or handling.

- Avoid Stress Points: Minimize stress points by securing thermocouple cables properly along their route. Use appropriate clamps, brackets, or cable ties to secure cables without over-tightening, which could damage the insulation or affect temperature readings.

- Ensure Proper Grounding: Proper grounding is crucial for accurate temperature measurement and to minimize electrical noise interference. Follow manufacturer recommendations for grounding techniques and ensure a secure connection to the ground point.

- Protect from Environmental Hazards: Shield thermocouple cables from environmental hazards such as moisture, chemicals, abrasion, and extreme temperatures. Use protective conduit, sleeves, or insulation where necessary to safeguard cables from damage.

- Verify Connections: Double-check all connections to ensure they are secure and properly terminated. Loose or faulty connections can lead to inaccurate temperature readings or system malfunctions.

- Calibrate Regularly: Periodic calibration is essential to maintain the accuracy of temperature measurement systems. Follow a regular calibration schedule as recommended by the manufacturer or industry standards to ensure reliable performance.

- Inspect for Wear and Damage: Routinely inspect thermocouple cables for signs of wear, damage, or deterioration. Look for cracks, fraying, or discoloration of the insulation, which could indicate potential issues that need attention.

- Clean as Needed: Keep thermocouple cables clean from dirt, debris, and contaminants that could affect their performance. Use gentle cleaning methods such as wiping with a soft cloth or mild cleaning solution as needed.

- Document and Track Maintenance: Keep detailed records of installation dates, maintenance activities, and any issues encountered. Maintain a log of calibration results and any adjustments made to the temperature measurement system.

- Train Personnel: Ensure that personnel responsible for installation, maintenance, and operation of temperature measurement systems are adequately trained. Provide training on proper handling, installation procedures, and troubleshooting techniques to prevent errors and minimize downtime.

- Stay Updated: Stay informed about advancements in thermocouple technology, installation techniques, and maintenance practices. Regularly review manufacturer guidelines, industry standards, and best practices to ensure that your temperature measurement systems are up to date.

In conclusion, thermocouple cables play a crucial role in the functionality and accuracy of thermocouple temperature measurement systems. By understanding the significance of cable material, construction, installation, maintenance, and calibration, users can optimize the performance and reliability of their temperature sensing applications. Investing in high-quality cables, coupled with proper care and calibration practices, is essential for obtaining accurate temperature readings and ensuring the success of diverse industrial processes, scientific experiments, and technological advancements.

As we look to the future, advancements in materials and design will likely lead to even more robust and versatile thermocouple cables.

TEMPSENS: Leading Manufacturer of Thermal and Cable Solutions:-

With over 45 years of expertise in temperature measurement, Tempsens stands as a leading manufacturer of thermal and cable solutions. Their extensive range includes both contact and non-contact temperature sensors, catering to diverse industrial needs. Tempsens' commitment to innovation and quality makes them a trusted partner in the ever-evolving world of temperature measurement.

FAQs

How Long Do Thermocouple Wires Last?

Numerous variables, such as the type of thermocouple, the environment in which it is used, and the operating parameters, might affect how long thermocouple wires last. In general, thermocouples are robust and durable, but their longevity can be influenced by some following factors such as, Temperature, Chemical Exposure, Mechanical Stress, Installation and Maintenance and Type of Thermocouple Cable.

As a general guideline, under normal operating conditions, thermocouples can last several years. However, in more demanding environments or high-temperature applications, they may have a shorter lifespan.

What Temperature Range Can Thermocouple Wires Measure?

The total temperature range for all thermocouple kinds is -200°C to +1800°C, albeit this greatly depends on the type. When choosing a thermocouple type for an application, there are a lot of things to take into account, and we would be pleased to help if we can. Note that these temperature ranges are approximations, and that actual performance may differ based on calibration, alloy composition, and other variables. Furthermore, thermocouples can give precise readings within the designated temperature ranges; however, when those ranges approach their extremes, their accuracy may decline.

For details visit at: https://tempsens.com/catalog/cables-wires/thermocouple-cables.htm