- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

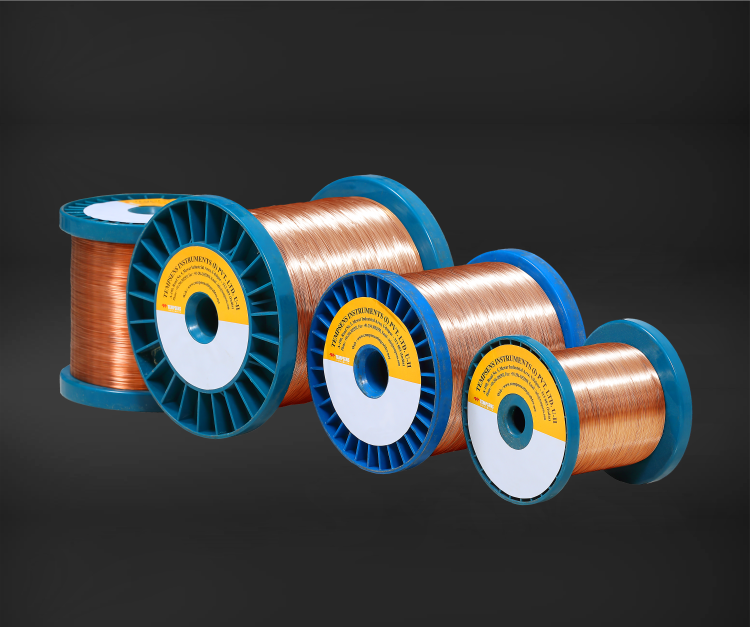

Understanding Nickel & Thermocouple Alloys

Nickel & Thermocouple Alloys are playing a vital role in the thermal industry due to its high melting point and excellent thermoelectric and mechanical properties.

Nickel alloys are a group of metallic materials that primarily consist of nickel as the base element, often combined with other elements such as chromium, iron, molybdenum, and cobalt. These alloys are known for their excellent corrosion resistance, high temperature strength, and other specialized properties, making them suitable for various demanding applications, including in the field of thermocouples, extension alloys, and resistance heating alloys.

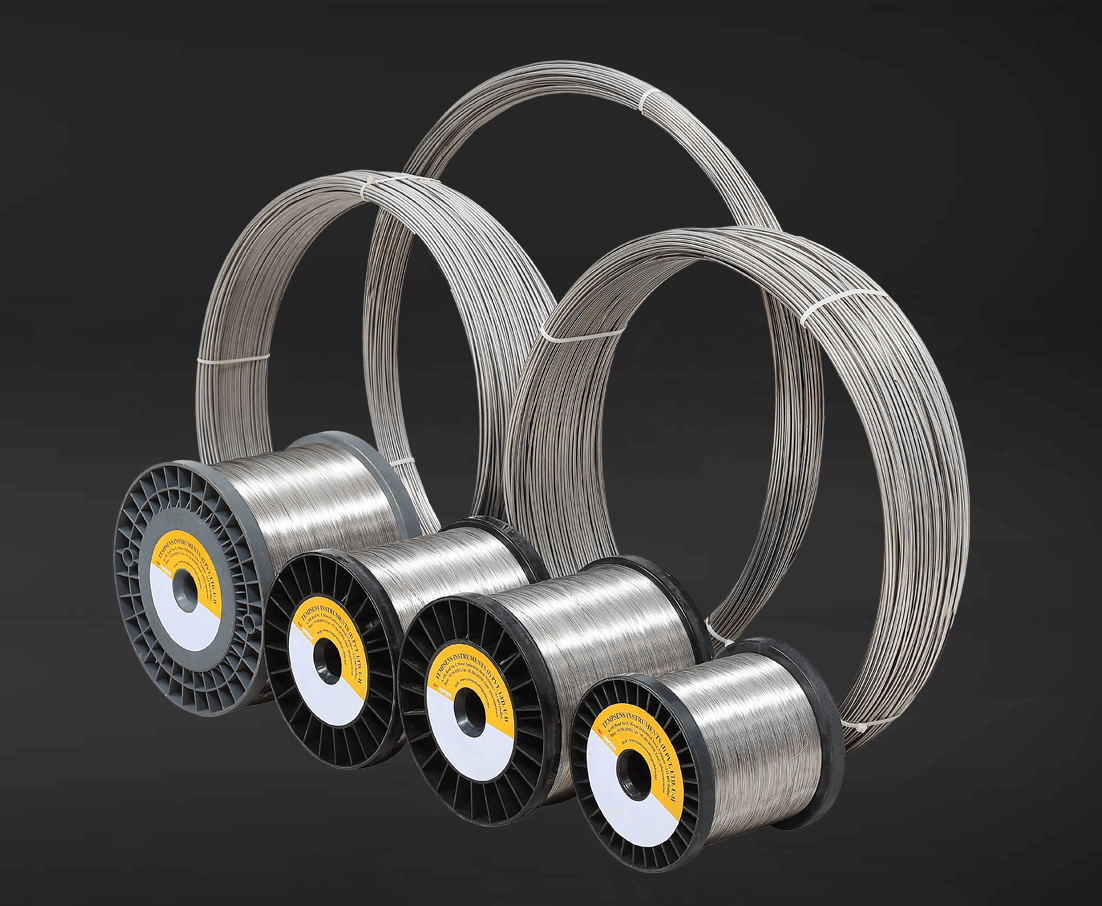

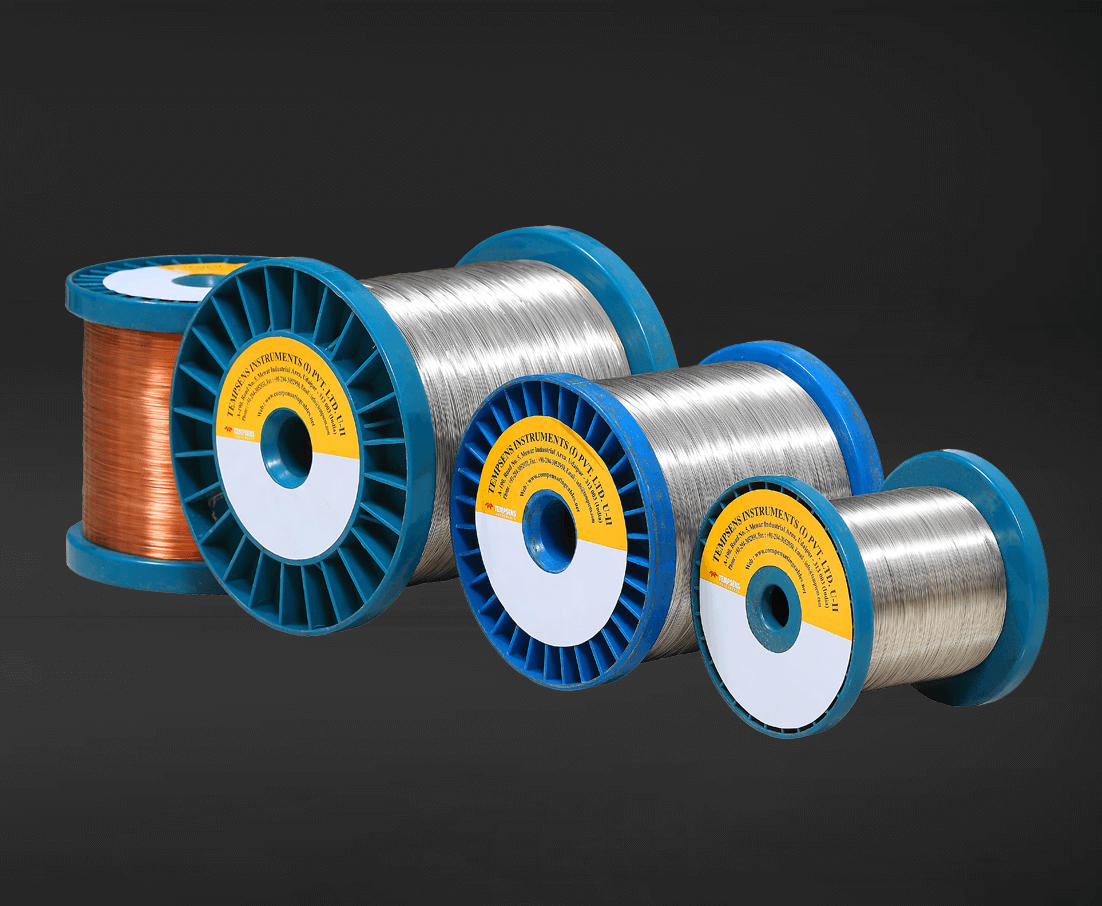

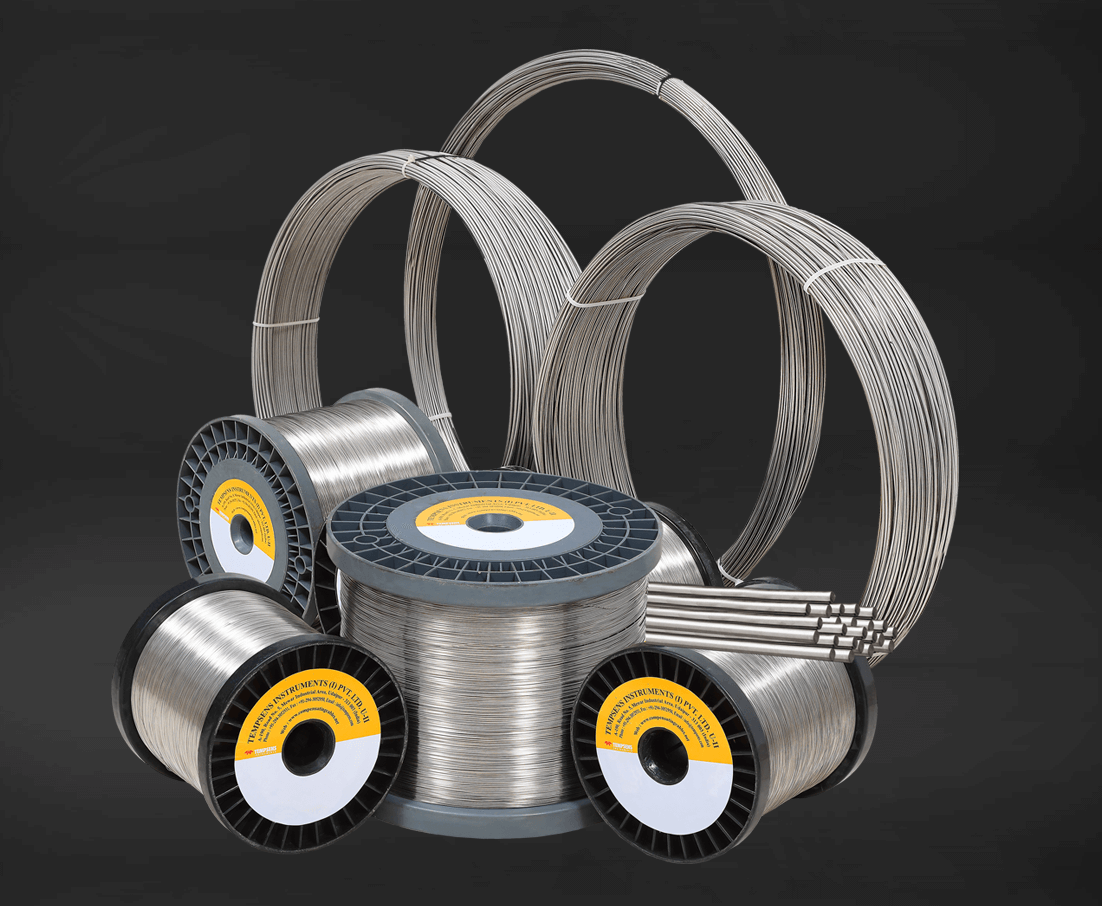

We manufacture a wide range of conductors in various types & sizes for high-temperature applications. We provide standard as well as custom-made products according to the customer's needs. Our lines are flexible and ready to meet the demand.

Tempsens Instrument has manufacturing process conforms to national & international standards for high-quality of wire conductors, bar and rods of Nickel & Thermocouple Alloys.

All Conductors, bar and rods are testing in the NABL accredited lab at our Udaipur facilities.

Major alloy types with applications -

- Thermocouple conductors - Instrumentation Cables, Making of thermocouple

- Extension / Compensating grades conductors - Cables

- Pure nickel grades conductors - Welding, Heater, Cables, wire mesh filters.

- Nichrome heating grades conductors - Heater, Furnaces.

- Cupronickel grades conductors - Heating mats, floor heaters, other heaters.