- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

SPNDs (Self-Powered Neutron Detectors)

- No need for power supply.

- Simple and robust structure.

- Relatively small mechanical “size” desired for in-core installation.

- Good stability under temperature and pressure conditions.

- Generate a reproducible linear signal.

- Low burn-up (dependent on emitter material).

Details

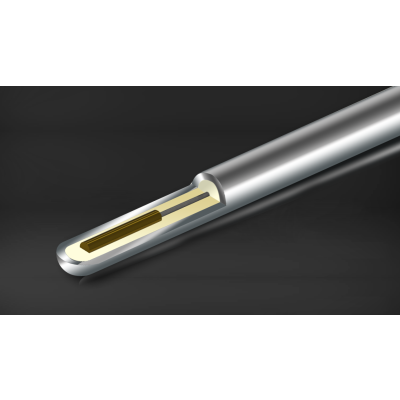

Self-Powered Neutron Detectors are being widely used to monitor in-core neutron flux for control, safety, and mapping applications because of their small size, ruggedness and simplicity. These detectors use the basic radioactive decay process of neutron activation material to produce an output signal. As the name implies, no external source of ionizing or collecting voltage is required to produce the signal current. Depending on the response time, these detectors are broadly classified as prompt and delayed response detectors. Prompt response detectors as Cobalt and Inconel are used in reactor protection and regulation applications, whereas the delayed response detectors like Vanadium and Rhodium are being widely used for Flux Mapping System.

They have been effectively used as in-core flux monitors for over twenty-five years in nuclear power reactors worldwide. The typical SPND is a coaxial cable consisting of an inner electrode (the emitter), surrounded by insulation and an outer electrode (the collector).

Specifications

|

Description |

Specification |

|

Mechanical structure type |

Integral, No integral |

|

Emitter Material |

Inconel 600, Rhodium, Vanadium, Cadmium, Platinum, Silver, Cobalt etc. |

|

Insulation Material (for Detector section and lead cable section) |

Magnesium Oxide (MgO), Alumina Oxide (Al2O3) |

|

Collector Material |

Inconel 600, Stainless Steel |

|

Sheath Material of lead Cable section |

Inconel 600, Stainless Steel |

|

Lead material of Lead cable section |

Inconel 600 |

|

No of lead |

One or two |

|

Emitter Diameter |

Can be made upon request |

|

Emitter length |

|

|

Collector Diameter |

|

|

Collector Length |

|

|

Cable section Diameter |

|

|

Cable Section length |

|

|

Cable Lead Diameter |

|

|

Collector and cable Sheath Thickness |

|

|

Connector Type |

LEMO Connector, BNC Connector, etc. |

|

Insulation resistance at 20°C |

≥ 1012 Ω |

|

Insulation resistance at 300°C |

≥ 108 Ω |

|

Production Quality testing

|

Weld joint Quality Test (liquid Penetration Test)

|

Key Features

Compared to other in-core detectors, they feature some advantages:

- Need no power supply.

- Simple and robust structure.

- Relatively small mechanical “size” desired for in-core installation.

- Good stability under temperature and pressure conditions.

- Generate a reproducible linear signal.

- Low burn-up (dependent on emitter material).

In addition, there are also some disadvantages:

- Limited operating range due to relatively low neutron sensitivity.

- Compensation for background noise required (for some emitters).

- Delayed signal response (for some emitters).