- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Why do we need Tube skin temperature measurements ?

- To determine accurate temperature data on the surface of the tube

- To withstand corrosive and harsh environment for prolonged period

- To secure weld attachments to the tube wall to fit any tube size

- Fast installation and quick replacement during maintenance period

- To monitor temperature in case of over heating of the tube/ pipe which leads to reduction of the life period

- To obtain maximum product flow through heat exchanger

What is the Tube skin thermocouple?

The Tube-skin thermocouple features a powerful, reliable, and suitable design to measure the surface temperature of the most critical, heavy-duty furnaces, heat exchanger, and reactors. Welded directly to the tube skin (surface), the tip of the tube skin thermocouple provides precise measurement of the surface temperature of the process tube. Aheat shield is added to prevent the addition of external/ambient gases and flame temperature on the hot junction, thereby providing more accurate temperature results.

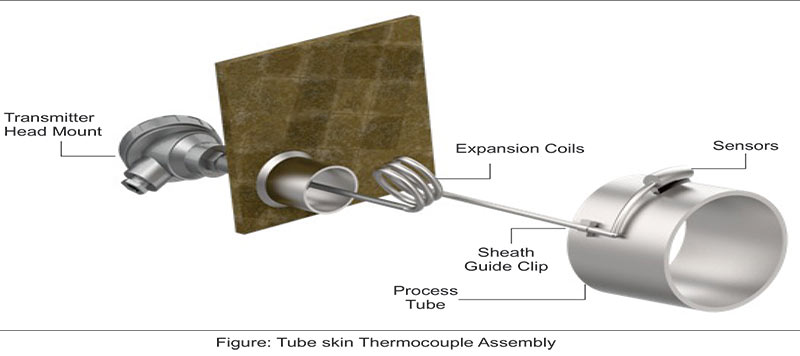

Tube skin Thermocouple Assembly

Expansion loops or coils are designed to avoid the effect of tube expansion which is subject to thermal growth. Mounting clamps are welded along the pipe to provide additional support. Mineral insulated cable (sheathed cable) is the flexible part of the sensor. It consists of a metal outer sheath of stainless steels or Inconel depending on the applications, which contains the insulated conductor wires, compressed within a high-density magnesium oxide composition. At one end of the sheathed cable, a non-insulated (grounded or ungrounded) junction, also known as measuring point (hot junction), is formed by welding the internal conductor together at the center of the weldpad. The measuring point is brought out closer to the tube to provide a faster and accurate measurement of the tube temperature.

Key Features

- Higher precision can be obtained with the addition of an optimized shield

- Easy to install

- Reliability combined with fast temperature response behaviour

- Mineral insulated with flexible sheath cable

- Customizable according to sheath diameter and sheath materials

- High mechanical strength and shock-resistant

- No special machining of the contact block is required to match the tube profile.

Application Areas

- Petrochemical and oil industries

- High temperature industries and corrosive environments

- Boilers, furnaces and ovens

- Gas and chemical industries

- Power plant technology

Technical Specification

| Element | K, N, E, J |

| No. of sensors | Simplex, Duplex |

| Hot junction | Grounded, Ungrounded |

| Sheath material | Stainless steel, Inconel |

| Sheath diameter | 12.7, 9, 8, 6 etc. |

| Response Time | Less Than 10 sec. |

| Temperature Range | 0-1200°C |

| Accuracy | Class 1, Class 2 |

Sensor Design

Tempsens provide custom build tube skin thermocouples as per the user requirements and drawings. Thermocouple assembly consists of different types of pad as illustrated below. Assembly also consists of an optional ceramic terminal block or head mounted transmitter

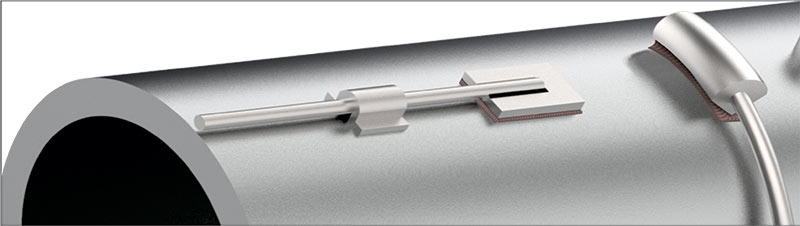

Knife Pad Type

The Knife-pad design includes a machined v-shaped block which forms a grounded junction to the tube surface

Features

- The design maximizes the accuracy of the sensor which helps to maintain optimum product flow and prevents tube from damage/rupture.

- The v-shaped block allows a full penetration weld between the sensor and the tube surface, which eliminates the potential air gap and protect against deleterious combustion gases, thus reducing substantial measurement inaccuracies.

- Suitable for any tube size due to v-shape, no special machining is required to match the tube profile.

- Longer life, accurate and reliable operations.

- Maximum thermal conductivity (between hot junction and sensing end of the assembly) and minimum thermal conductivity (between hot junction and the gases)

Response Time <5 Sec.

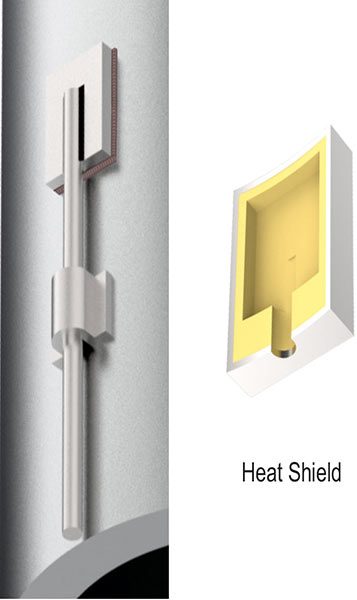

Weld Pad Type

Weld pad design provides a simple, reliable tube skin thermocouple for average duty furnace

- The weld-pad is marked to match the diameter of the mineral-insulated cable, which allows the hot junction of a thermocouple to be adjacent to the measuring surface.

- It is designed for plain and contoured surfaces.

- Weld-pad with ungrounded junction does not create addition inaccuracies.

- Weld pads can be mounted longitudinal or right-angled to the pipe surface and can be incorporated in any MI-cable diameter.

- Weld pads are less accurate than knifeedge designs while maintaining similar repeatability.

- Heat shield can be used to improve reliability of the reading accuracy

Response Time <10 Sec.

Curved Weld Pad

The Curved Weld design consists of a weld pad attached to a guide channel and heat shield

- The Curved Weld design allows the thermocouple to be replaced without the need to perform any re-welding on the process tube.

- Once the guide channel has been welded on the surface of the tube, the thermocouple can be replaced without interrupting the process.

- The design allows the welded part to be attached to the tube in absence of the sensor.

- Grounded and ungrounded junction can be formed.

- Heat shield can be used to improve reliability of the reading accuracy

- Customize designs are available according to the application.

Response Time <10 Sec.

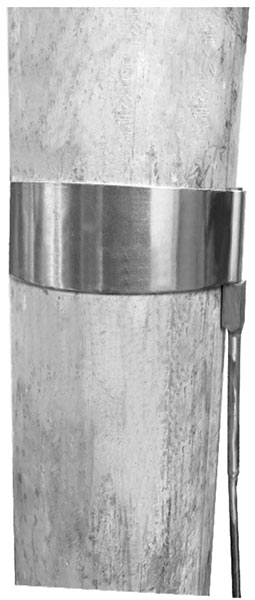

Clamp-on Pad

The Clamp-on pad consists of adjustable fitting for sensing the temperature of pipe

- Adjustable clamp allows sensor to make good contact with the pipe surface.

- Easy mounting and quick mounting brackets.

- Used for measuring process temperature of hot and cold water loops in building.

- RTD’s are also available for process fluid surface.

- Extension cable is highly flexible, permitting bending to a radius of 3 cm.

Response Time <10 Sec(Thermocouple) , Response Time <6 Sec(RTD)