- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

What is Swaged Thermocouple?

Swaged tip thermocouple is special-purpose thermocouples in which thermal sensing element area is reduced by swaging, which leads to a faster response from the sensor. The thermocouple is manufactured in rugged construction which allows safeguarding the sensor against the effects of vibrations, therefore increasing its useful life and preventing inoperativeness.

Swaging is a type of forging process in which a part is hammered and reshaped using rotary dies. The method of swaging dies runs at over 500 blows per minute until the desired final, reduced diameter is achieved. The swaging process does not compromise the ruggedness of the structure but helps to increase the tensile strength as the process strengthens the grain structure of the material. This process gives the thermocouple forging the advantages of being simple in construction and inexpensive to manufacture. The process also adds high resistance against being burned up.

These types of thermocouples have large diameter throughout the length to hold out against harsh environmental conditions, except the bottom swage area where the sensor is located. The sheath can be bent, twisted and flattened to suit particular installations. The heat generated on the swaged tip mineral insulated allows the sensor to be formed in a particular shape without disturbing performance.

Features of Swaged Thermocouple

- Fast response as a result of lower thermal mass at the tip.

- High accuracy and stability throughout operating with high insulation resistance.

- Rugged construction provides high strength and is suitable for harsh conditions.

- Cost Effective as compared to expendable thermocouples.

- Ceramic coated tip can be used to measure temperatures of molten metal with high

accuracy without damaging the sensor. - Can be used with digital pyrometer and other instruments. Durable alternative for

expandable thermocouple.

Swaged Thermocouple Installation

Technical Specification

| Element | K, N, E, J, R, S, B. |

| Insulation material | Mineral Magnesium Oxide (MgO) |

| No. of sensors | Simplex |

| Hot junction | Grounded, Ungrounded |

| Sheath material | SS316, SS310 & Inconel 600 |

| Sheath diameter | 12.6, 10, 8, 6 etc. |

| Response Time | Less Than 10 sec. |

| Temperature Range | Depending on material |

| Process connection | Customizable according to applications. |

| Length of probe | Upto 2000mm. |

| Swaged Outer Diameter | Upto ~1mm for a length of upto 100mm. (Varies acc. to the sheath diameter). |

Applications of Swaged Thermocouple

- Molten metal and non-metal temperature measurements

- Smelting and casting process.

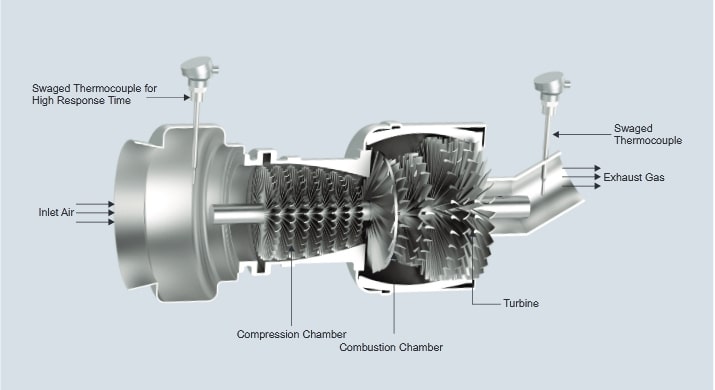

- Aircraft and automotive engines

- Gas turbines and Ground equipments

- Temperature measurement of fluid flow in extreme conditions