- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

B Type Thermocouple

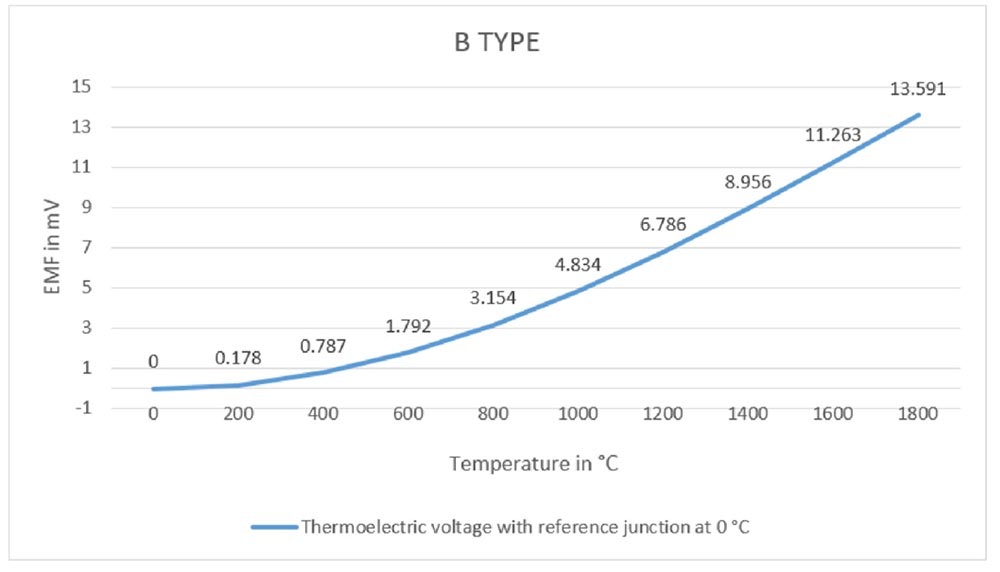

The Type B thermocouple are suited for use at upto 1800 °C. These are used in extremely high temperature applications. Specialty of B Type thermocouple is that it has the highest temperature limit in all the other type of thermocouple. These thermocouple produce the same output at 0°C and 42°C, limiting their use below about 50°C. The emf function has a minimum around 21°C, meaning that cold-junction compensation is easily performed, since the compensation voltage is essentially a constant for a reference at typical room temperatures.

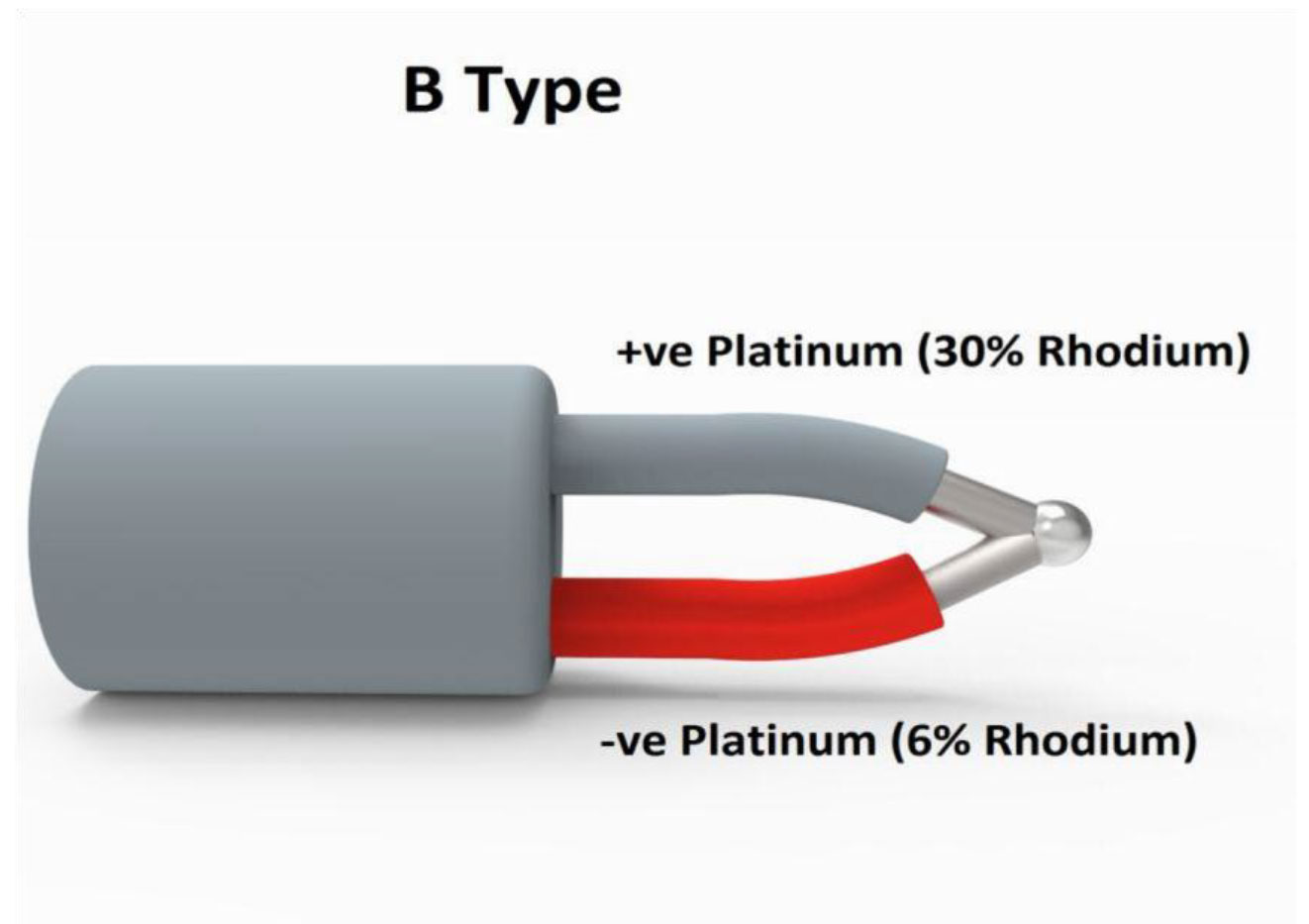

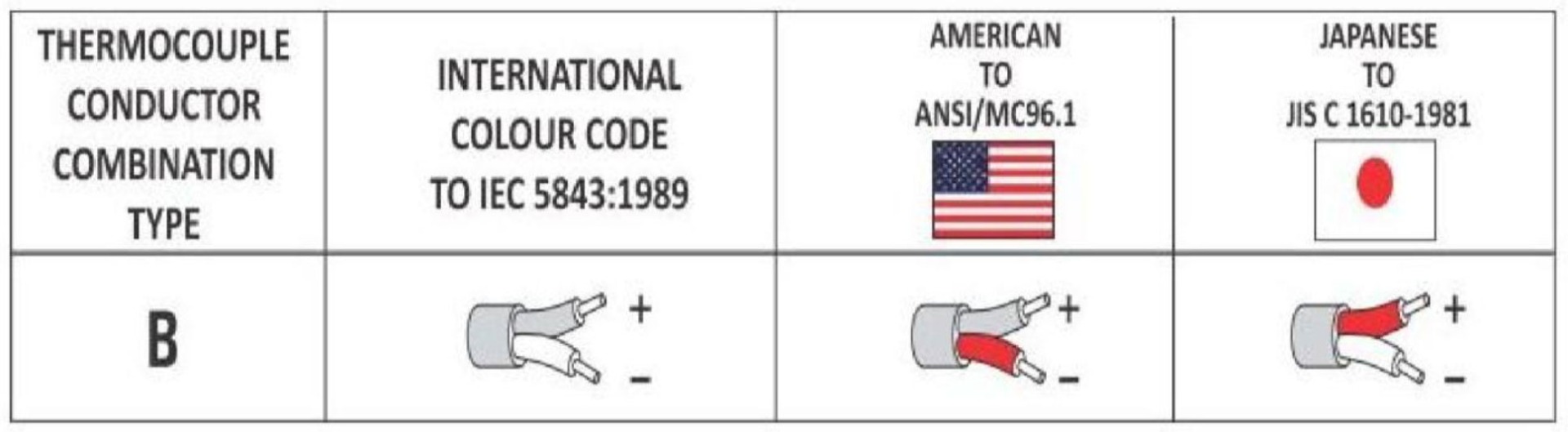

Composition:

Type B Thermocouple is composed of a positive leg which is 70% Platinum, 30% Rhodium and a negative leg which is 94% platinum, 6% Rhodium. When protected by compacted mineral insulation and appropriate outer sheath, Type B is usable from 600 to 1704°C, (1100 to 3100°F).

Why to prefer Type B Thermocouple?

- Maintains a high level of accuracy and stability at very high temperatures

- Highest temperature limit of all of the termocouples

- Stable voltage generating equipment that possesses the quality of resisting high temperature oxidation.

- Wide measuring range

- High mechanical strength.

- Good pressure-resistant

Temperature Range:

- Thermocouple grade wire, 32 to 3100F (0 to1700C)

- Extension wire, 32 to 212F (0 to100C)

Accuracy (whichever is greater)

- Standard: +/-5%

- Special Limits of Error: +/- 0.25%

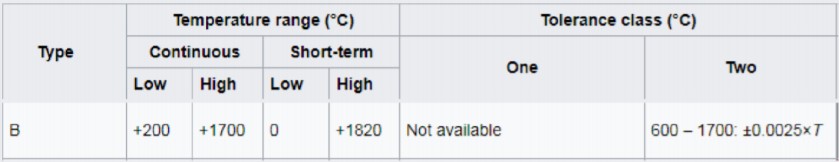

Tolerance Class:

Type B Insulation Material:-

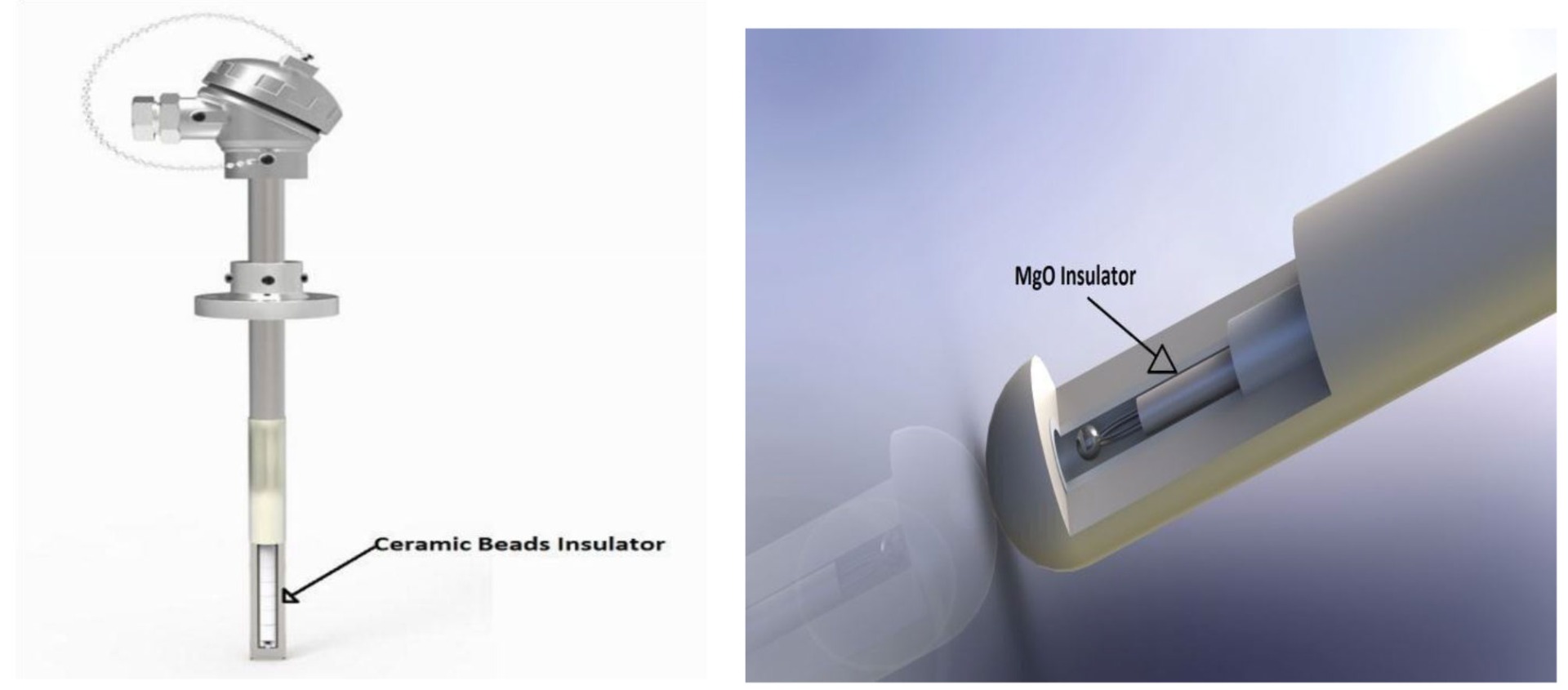

In Type K Thermocouple mainly two type of insulation is used firstly Ceramic beads insulation is used as it is a lightweight insulating product. It is made from high purity alumina-silicate materials. It has low thermal mass which means that it does not retain heat, low thermal conductivity and is an extremely effective insulation material as it can withstand high temperature of 1260 °C so it is best suited material for Type K thermocouple.

Secondly compacted mineral insulation and outer metal sheath (MgO) is used. Magnesium Oxide has a high dielectric strength, responds quickly to temperature changes and is very durable. It has typical Composition of the Standard Quality MgO (97%) and the High Purity MgO and AI2O3.

Magnesium Oxide insulation is recommended for K Type thermocouple when Thermocouple are to be immersed in liquids, high moisture, corrosive gases or high pressures. The thermocouple can be formed to reach otherwise inaccessible areas.

EMF VS Temperature Graph for

Pros and Cons

Pros:

- Provides highest accuracy in comparison to other thermocouple

- Measures at a wide temperature range: Continuous : 200 - 1800°C oShort : 0 - 1850°C

- Very fast response for higher temperatures (above 500°C)

Cons:

- Provide least output emf per degree Celsius change in temperature

- Costlier than other types as Platinum alloys are used

- Slower response for measurements below 500°C.

- Cannot be used for sub-zero temperature measurements

- The type B has a lower output than the other noble metals (type R & type S) attemperatures below 1,112F (600C).

Uses:

- Cement Processes and Incinerators

- High Temperature Industries

- Hot Gas temperature measurements

- Inert and Oxidizing Applications