- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

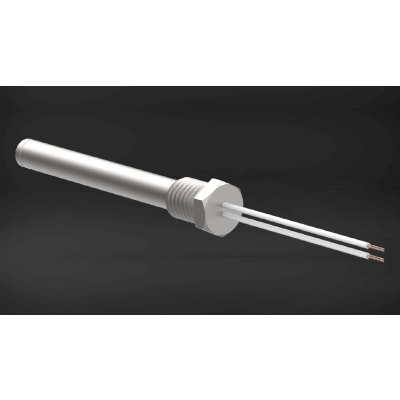

Cartridge Heater 12.5 mm x 50 mm 325 W 220 VAC

High Temperature Lead Wires

High Impact Ceramic Cap

Nickel Chromium resistance wire

High Purity Magnesium Oxide insulation

Stainless Steel Sheath

Details

Hot Rod Cartridge Heaters are designed to provide uniform heating and excellent heat transfer rate throughout the heating surface. Facilitated with individually controllable heating zones, various process requirements such as zone specific heating and distributed wattage requirement can be achieved with precise and uniform temperatures. Heaters are constructed with minimal spacing between sheath and heating element to maintain lower internal temperatures which results in smaller sized heaters operating at higher watt densities.

Constructed of high grade Nickel Chromium resistance wire wounded on specially designed cores, separated from metal sheath using high purity magnesium oxide fill, all centered and tightly compacted in SS/Inconel tubing through refined swaging process, results in heaters with minimal air gap, high resistance to corrosion and oxidation, and increased life which makes Marathon make cartridge heater best in class with high performance and longer durability.

Specifications

| Temperature Range | Up to 760°C |

| Nominal Diameter | 12.5 mm |

| Length | 50mm |

| Lead length | 254mm |

| Lead Termination | Swaged in leads |

| Watt Densities | Up to 400 W/in2 |

| Power Rating | 325 W |

| Supply Voltage | 220 VAC |

| Sheath Length Tolerance | ±3% |

| Wattage Tolerance | +5%, -10% |

| Resistance Tolerance | +10%, -5% |

Key Features

- High Temperature Lead Wires for temperatures up to 550°C

- High Impact Ceramic Cap retards contamination and is suitable for high vibration applications

- Nickel Chromium Resistance wire for maximum life, evenly wound for even heat distribution

- High Purity magnesium oxide fill selected for maximum dielectric strength and thermal conductivity, highly compacted for maximum heat transfer

- Stainless steel sheath / Inconel sheath for oxidation and corrosion resistance in wide variety of environment

Standards

- UL

- CSA

- RoHS