- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

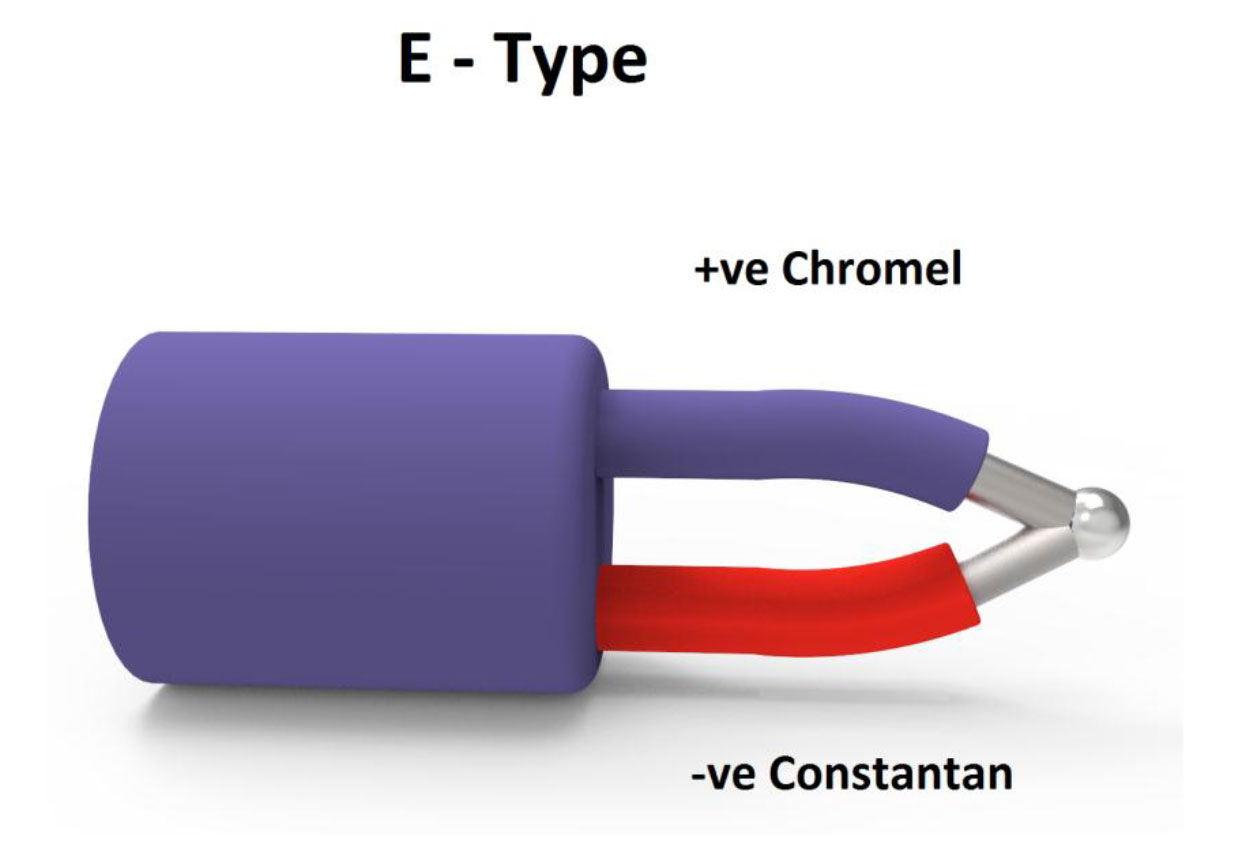

Type E thermocouple

The Type E thermoPros and Cons:- couple is a commonly used thermocouple which provides stronger signal and higher accuracy as compared to Type K and Type J at moderate temperature range of 1000°F and lower. The Type E has higher stability when compared to type K thermocouple due to which it provide good accuracy.

Why To Prefer Type E Thermocouple:

- Has the Highest EMF produced per degree than any other standard

- Provide High output (68μV/°C) due to which it is well suited to cryogenic

- Provide High Resistance against

- It is non-magnetic

- Provide wide-range of -50°C to +740°C and narrow range of -110°C to+140°C.

- Type E can come in variety of designs suited to differentapplications:-

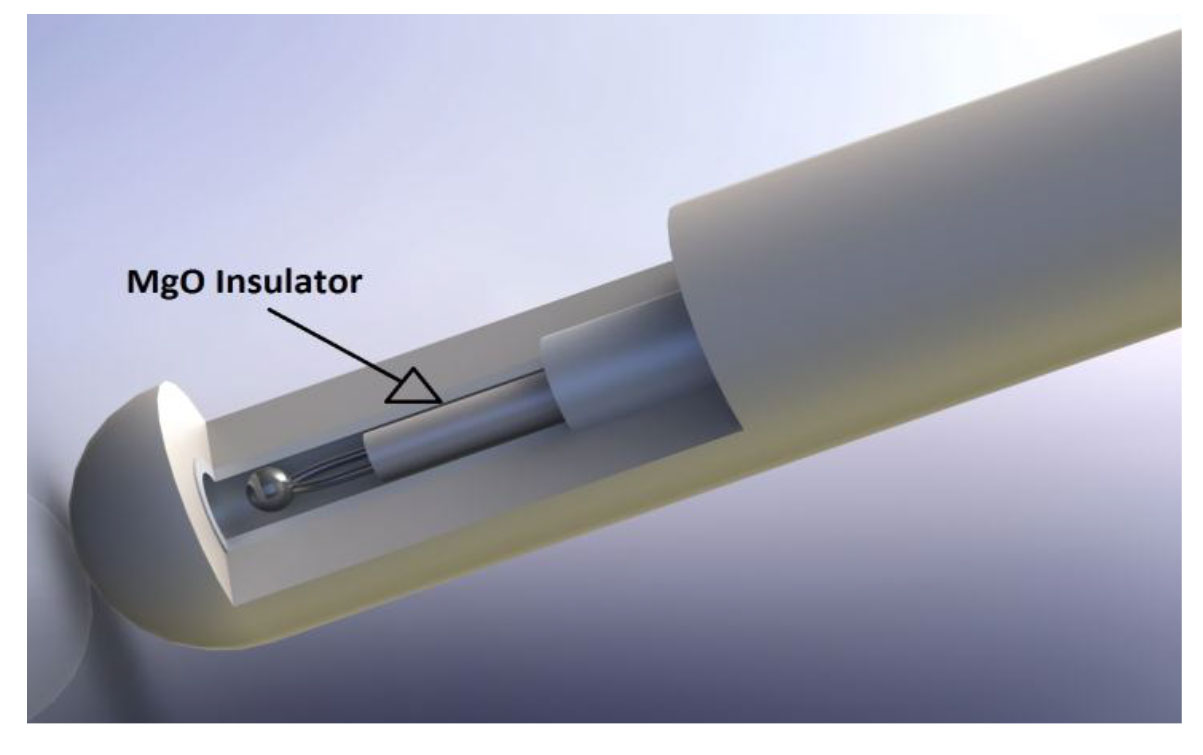

- Mineral Insulated Type E:-Metal sheath insulated with magnesium oxide powder also called

- Cable/Wire Type E:- Flexible sensors in PVC,PTFE or Glass Fibre. Many cold and hot-end

- Type E with Metal Sheath:- High Temperature design with metalprotection sheath.

- Type E Inserts:- Rigid metal tubes and ceramic insulators are commonly used in pocket, thermowell or head

Composition:-

In Type E Thermocouple positive leg is composed of approximately 90% nickel, 10 % chromium which is commonly known as Chromel and a negative leg, which is approximately 95% nickel, 2% aluminum, 2% manganese and 1% silicon commonly known as Constantan.

Type E Insulation Material:-

In E Type Thermocouple mainly MgO insulation is used. Due to many desirable characteristics of MgO such as fast response, compact size, broad temperature range, formability, weld ability, durability, accuracy, thermal shock and vibration resistance makes it an excellent choice for virtually all laboratory or process applications. The standard MgO insulation consist of ANSI/ASTM standard limits of error conductor material and standard (96%) pure insulation.

MgO Insulation provide initial calibration tolerances for thermocouple at the temperature range of 0 to 750 °C. Its standard tolerance is +2.2°C or +0.75°C % which best suits for these thermocouple.

Type E Temperature Range:

- Thermocouple grade wire, -454 to 1600°F (-270 to870°C)

- Extension wire, 32 to 392°F (0 to200°C

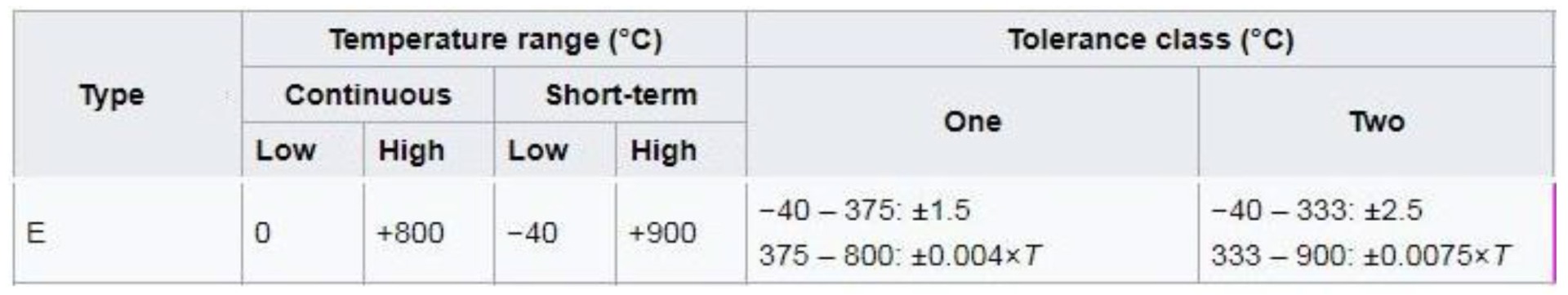

Type E Accuracy (whichever is greater):

- Standard: +/- 1.7°C or +/- 0.5°C%

- Special Limits of Error: +/- 1.0°C or 0.4°C%

Tolerance Class:-

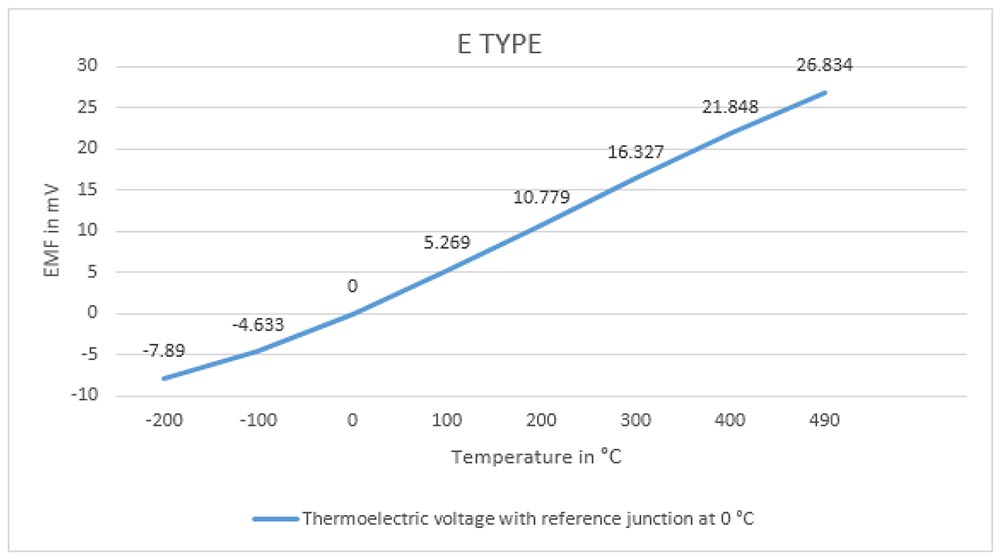

EMF VS Temprature graph for E type Thermocouple

Pros and Cons:

Pros:

- Can be used in Sub-zero, Oxidizing and Inert applications

- Provides highest output per degree Celsius(68μV/°C).

- Fast response applications

- Stable Output throughout the temperature range

- High Accuracy

Cons:

- Not suitable for vacuum or low oxygen applications

- Type E thermocouples should not be used in Sulphuric environment

- Costly when compared to Type k

Uses:

- For Cryogenic Applications.

- Applications where magnetic fields are generated as E type is non-magnetic in nature

- Aerospace industry where fast response is required

- Gas temperature measurement in a flow chamber