- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Thermal Cycling

What is Temperature Cycling?

Temperature Cycling (Thermal Cycle) is the process of cycling through two temperature extremes, typically at relatively high rates of change.

Why Temperature Cycling is used??

Thermal Cycle or Temperature Cycling is carried out on materials to ascertain the resistance of exposure to alternating extremes of low and High Temperatures. Performing temperature cycling test on the components will assist in determining:

- Existing thermal coefficient mismatches

- The sensitivity of these mismatches to be repeated temperature excursions

Thermal mismatch of materials can cause hermetic seal failures, solder joint cracking, damages to leads and markings and many other. Thermal Cycling testing is frequently utilized, particularly in the electronics industry. It exposes devices and components to temperature fluctuations, causing component fatigue and, in particular, interconnection fatigue. Cracking due to fatigue, for example, is one of the most common failure modes in electronics, making it a crucial factor to include in reliability analysis.

Tempsens solution

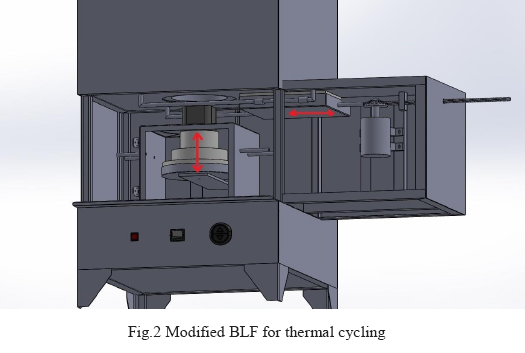

Tempsens made standard Bottom loading furnace (BLF) is modified to be used for Thermal Cycling. Bottom Loading Furnaces (BLF) have opening gate below the furnace and the bottom door is movable in order to serve the loading and unloading of material into the furnace. Bottom door moves by the use of a linear actuator.

The material is loaded on movable bottom door which moves into furnace and treated at high temperature for a fix period of time then the bottom door loaded with material can be lowered to a lower temperature and then the procedure can be performed as per process requirements.In order to make sure that there is no heat leakage from the furnace when the bottom door is down; an alternative closing door is provided which will move horizontally to close the furnace. Alternate door moves by use of rack and pinion gear arrangement using motor.

When the bottom door is in its lowest position it touches limit switch and side door is activated to close the furnace. When the bottom door is closing the furnace, side door does not move and vice versa. Purging arrangement is provided to ensure environment as per requirement of the process.

Industry

- Electronics

- Pharmaceutical

- Automotive

- Medical

- Dental

- Military

Further Reading