- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

Temperature Measurement For Continuous Casting Machine

Continuous Casting Machine and Brief process of CCM

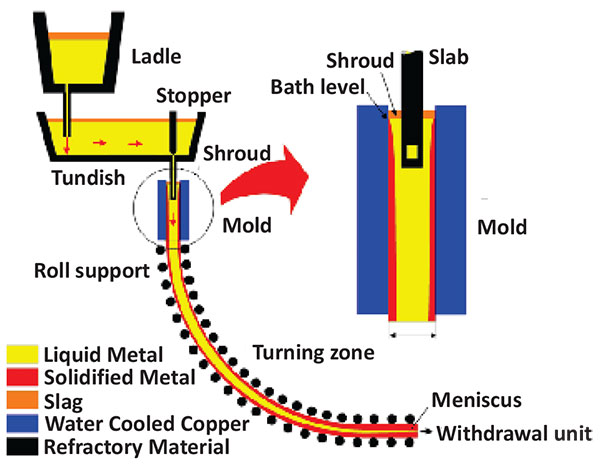

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "SemiFinished" billet, bloom, or slab for subsequent rolling in the finishing mills. The continuous casting machine has evolved to achieve productivity, quality and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardized production of a product, as well as providing increased control over the process through automation.

In CCM Molten metal is poured into tundish and after tundish it moves to mould. A mostly rectangular strand profile (Billet) is formed out of liquid steel with a mould. Afterwards, the strand profile has to be cooled down in several levels. Depending on the size of the factory there can be several strands too. After the steel strand has left the cooling zone, it is completely set. Afterwards it gets usually cut with the help of blowpipes into the desired lengths. The typical temperatures of these billets are in the range between 800 °C and 1000 °C.

What is the Need of Temperature Measurement

We all know that the temperature plays a crucial role in this complete process. If the temperature remains high or low than actual, it will affect the complete process like reduce the quality and productivity of material, increase the production cost etc. That is the reason why we need to monitor the process with temperature measuring instrument and automated the complete process

Why we need Pyrometer for this particular application?

As the object is moving in semi-solid state we can't use thermocouples (contact type temperature sensor) here as it will harm the semi solid material and also there is a chance of sensor getting damaged due to the motion. Here comes the need of non-contact temperature sensor and as pyrometer works in IR principle, it provides the much needed solution.

Site Challenges in CCM

- The environment is very harsh and dusty.

- The site ambient temperature is very high up to 70°C or 80°C.

What we offer

The AST A250 PL is most suitable and specially designed pyrometer for such type of applications. Environment being harsh and also high ambient temperature, we suggest water cooling for safety and long life of pyrometer

This AST A250 PL and accessories has the following features:

- Very fast response time with in mille seconds and adjustable as required and wide temperature range (210-3000°C).

- Bluetooth Communication for parameterization, you can connect pyrometer with your android mobile and change parameters remotely.

- Supplied with water cooling jacket and junction box for smooth process and safety of instrument.

- User selectable Analog output for automation of process.

- Laser or through the sighting options are available. (As per customer requirement)

- With Software it can easily be connected to a local PC/System, which will give runtime temperatures and graphical trend also.

Installed AST A250 PL in CCM Line

Installed AST A250 PL in CCM Line