- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

-

Email

enquiry@tempsens.com -

Phone

+91-9358835576

Manifold Heaters for Plastic Injection Moulding

Plastic injection molding are heavily utilized to create each and every of those items which are used on daily basis at your home or business establishments. It is the fastest way for shaping plastics accessible and available around. There are numerous advantages of plastic infusion forming process including dependability and cost viability. The items that are delivered with the assistance of this procedure, for the most part don't require anymore wrapping up at all.

How does it work

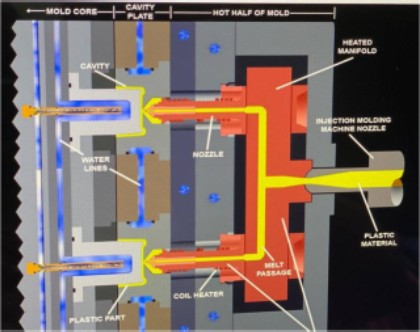

In this procedure, all the equipments utilized are modern and proficient, additionally called as the plastic injection mould machines. The hardware included is overwhelming and can even measure a huge number of pounds. It is just because of these substantial machines that the finished items are of the best quality all times. This machine warms up the plastic to convey it to its fluid structure. This demonstrates that the machines need to endure higher temperature and require exceptionally sophisticated parts for the reason.

When the plastic stuff is injected into the concerned mould or the cavity by way of gates, it gets into the specific shape of the mold, after the plastic gets cooled in the mould; it is automatically ejected out of it. These cavities may be used for getting desired plastic into almost all type of shapes. There are pricing consideration while designing plastic stuff and the pool of experienced engineers makes out the cost trade-offs of diversified design features

Our Model for this Application

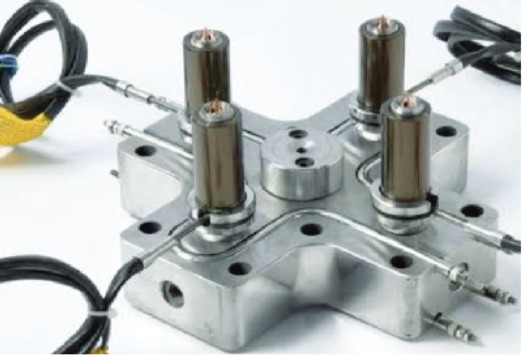

Our Component product Manifold heater is almost used in this application with different Customized sizes. In this photo heated manifold is shown which is use to maintain temperature in this process. Manifold heater is the most cost effective solution to take temperature in this application. Moreover it require no maintenance from the operator part to run the equipment. Moreover this is very easily removable as well as installing time is very less.