- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

How to choose the right Thermal Imaging Camera for your application ?

How to choose the right Thermal Imaging Camera for your application ?

Thermal imaging cameras are one of the most important predictive maintenance tools that are used in various process industries.These cameras are very helpful to identify any failure occurring in the machines or equipment.Thermal imaging Cameras detects the infrared energy emitted by the object and convert it into a thermal image which enables the user to identify hotspot and cold spot very easily.Thermal imaging cameras really help the plant maintenance team to avoid any kind of sudden breakdown or shutdown of the plant. Nowadays almost every industry is getting serious regarding predictive maintenance with thermal imaging cameras.Using thermal imaging cameras in your plant for maintenance purposes will also provide good return on investment.

Before choosing a thermal imaging camera for your application you must know some important features and their importance.So in this blog we will cover those important features of thermal imaging camera that must be kept in mind before choosing a thermal imaging camera.

Below Points to consider before choosing a Thermal Imaging Camera ?

- FIXED OR HANDHELD TYPE: There are two types of thermal imaging camera available in the markets i.e. Online thermal imaging camera also known as fixed type thermal imaging camera and Handheld thermal imaging camera. To choose between these two types first you need to analyze your own need and purpose to choose a thermal imaging camera. If you want to do a continuous thermal imaging of your application then you must opt for a fixed type thermal imaging camera. And if your application is such that you can perform periodic thermal imaging for their maintenance and are not critical enough then you can opt for handheld thermal imaging cameras which can be used to perform thermography in the entire plant.

Fixed Thermal Camera

Fixed Thermal Camera

Handheld Thermal Camera

- CAMERA RESOLUTION: Detector resolution is the number of pixels available in the thermal imaging camera to obtain an image. The more pixels available in the camera the better image quality and temperature accuracy you are going to get. There are various resolution cameras available in the market ranging from 80x60 to 1024x768. If your application demands just hotspot detection then you can choose a low resolution camera like 160x120 resolution but if your application demands more detailing of thermal image then you must opt for a high resolution thermal imaging camera like 640x480 resolution. If the distance between the object and camera is more then also you should choose a high resolution thermal imaging camera for your application.

- TEMPERATURE RANGE: Before choosing a thermal imaging camera you must know the lowest and highest temperature of your equipment or process then choose a thermal imaging camera of that range or higher.So that you can get an accurate temperature measurement.

- EMISSIVITY AND REFLECTIVITY CORRECTION: Every material has their own ability to emit infrared radiation which is known as emissivity.The thermal imaging camera that you choose must have a emissivity selection feature from 0 to 1 so that you can get an accurate temperature. While using thermal imagers you should also take into account the reflected temperature from a shiny material.

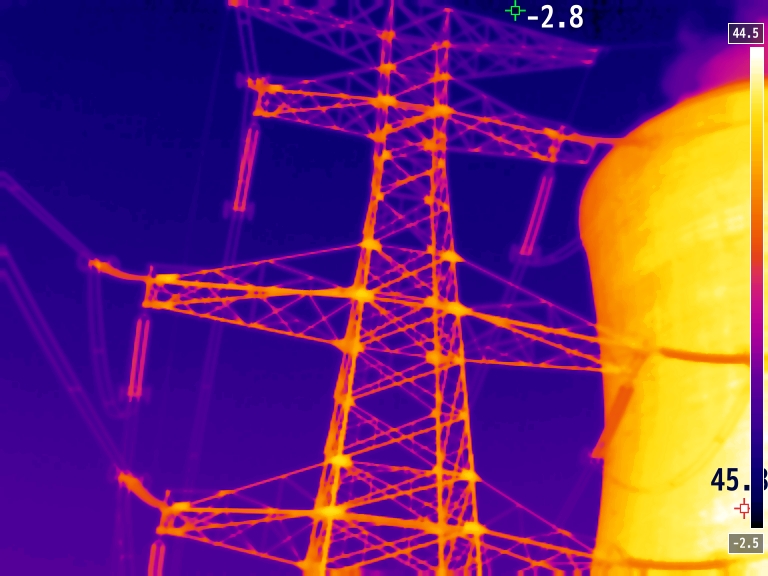

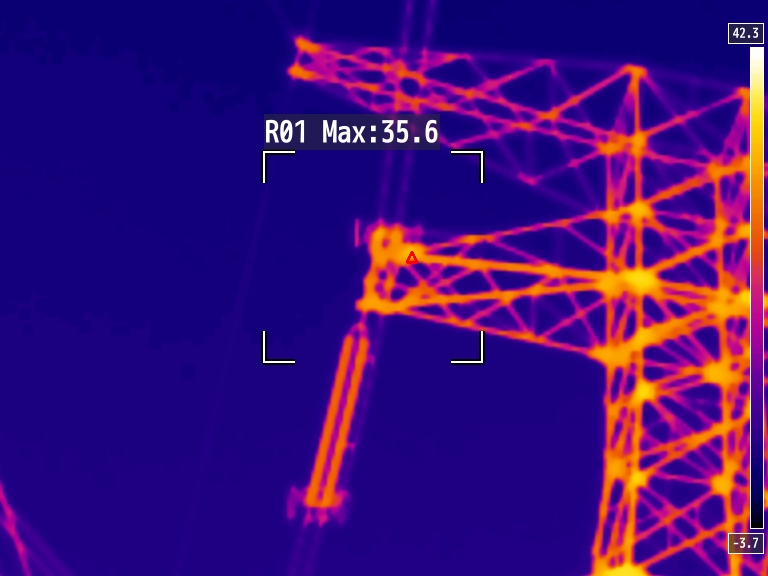

- LENS SELECTION: Thermal cameras are having lenses to focus the IR radiation on to a detector. A lens should be chosen according to the distance between the object and camera and your application requirement. For example the figure (a)the image is taken from a lens having a field of view of 25° x 19° but as you can see the distance between the camera and object is more so we are not able to see anything clearly like the insulators and conductors. But in fig (b) the thermal imager used is having a field of view of 12°x 9° that is a narrow field of view which is enabled us to have a much detailed and clearer image.

Fig. (a) Lens: 25° x 19°

Fig. (b) Lens: 12° x 9°

- OTHER FEATURES: The thermal imaging camera that you choose should also have some important basic features like digital camera, voice annotation/text annotations,auto focus capability,auto level span and auto calibration. Now these features will make your thermal image analysis more easier and efficient.

At last we want to conclude that thermal imaging cameras are really important for predictive maintenance of your plant. We hope this article will be helpful for you.Just look for the right thermal imaging camera for your application. You can contact us for more details and assistance regarding thermal imaging cameras.