- Home

- About

- Products

- Contact Temperature Sensors

- Cables & Wires

- Mineral Insulated Cables

- Nickel & Thermocouple Alloy

- Industrial Heaters

- Heating Cables and Mats

- Non Contact Temperature Sensors

- Industrial and R&D Furnaces

- Temperature Calibrators

-

Circulating Chiller

- Services

-

Special Products

- Thermal Profiling System

- Industries

- Resources

- Contact Us

- Shop

-

Email

enquiry@tempsens.com -

Phone

+91-9358835576

Heaters for Form Fill Sealing Machine

A Vertical form fill sealing machine is a type of automated assembly-line product packaging system, commonly used in the packaging industry for food, and a wide variety of other products. The machine constructs plastic bags and stand up pouches out of a flat roll of film, while simultaneously filling the bags with products and sealing the filled bags. Both solids and liquids can be bagged using this packaging system.

How Does FFS machine Work?

The typical machine is loaded with a continuous flat roll of plastic film labeling and art work applied to the exterior or interior of the film. Note that while plastic is the most commonly used packaging material in the food industry. The technology can also be used to form continuous metalized foil/film. For some products the film may first be fed through a sterilizing chemical bath and dryer prior to use in the packaging system.

Our Model for this Application

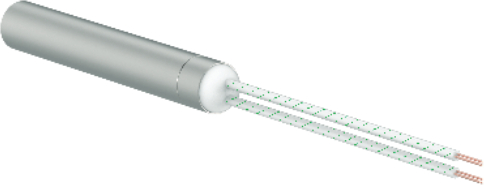

Cartridge Heater

The engineers at marathon heater instruments have developed a cartridge heater that exceeds the performance and durability of other cartridge heater. High temp. Lead wire for temp. up to 450℃. Nickelchromium resistance wire for maximum heater life, evenly wound for even heat distribution. TIG Welded end disc to prevent contamination and moisture absorption. Cartridge heater is the most cost effective solution for this particular application as it requires no maintenance from the operator part to run the equipment.